Deep Groove Ball Bearings have a very wide range of applications. They are suitable for high and ultra-high speeds, can withstand radial and axial loads in both directions, and require almost no maintenance. Deep Groove Ball Bearings are widely used types of bearings, Deep Groove Ball Bearing Supplier THB offers a variety of designs, variants, and sizes for their Deep Groove Ball Bearings.

Single Deep Groove Ball Bearings

Single Deep Groove Ball Bearings come with two designs: open type or sealed type (with seals or dust caps). Open bearings can also be fitted with seals or dust caps, with grooves on the side of the outer ring.

Bearings with Filling Slots Single Deep Groove Ball Bearings

Bearings with filling slots Single Deep Groove Ball Bearings have a filling notch on both the inner and outer rings, allowing them to accommodate more steel balls than standard Deep Groove Ball Bearings.

Bearings with filling slots have a greater radial load capacity than those without, but their axial load capacity is limited. They also cannot reach the speeds that bearings without filling slots can attain.

Bearings with filling slots Deep Groove Ball Bearings come in two designs: they can also come with or without snap ring grooves. Open bearings with filling slots can be equipped with dust caps on the outer ring with a snap ring groove.

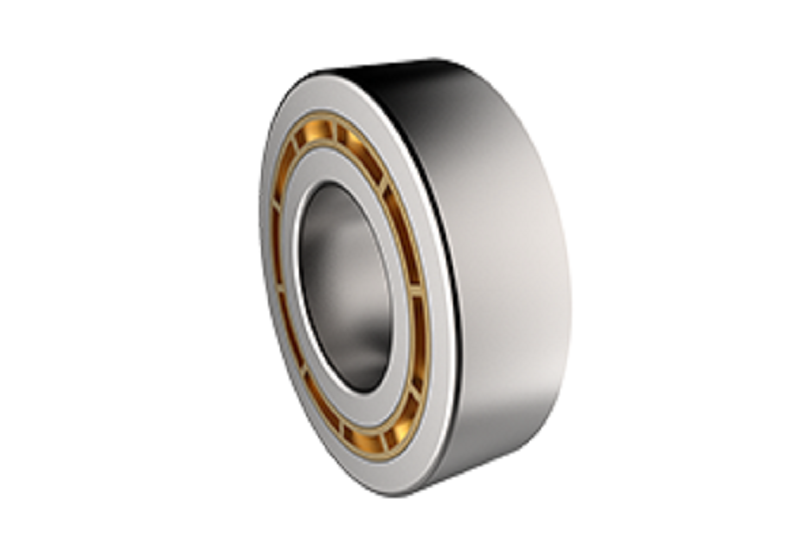

Double Deep Groove Ball Bearings

Double Deep Groove Ball Bearings are suitable for applications where the load capacity of a Single Deep Groove Ball Bearing is insufficient. For Double Deep Groove Ball Bearings with the same outer and inner diameter as a Single Deep Groove Ball Bearing, their width is greater, and the load capacity is significantly higher than that of a Single Deep Groove Ball Bearing.

Double Deep Groove Ball Bearings come in only one design: open type (without seals or dust caps).

Deep Groove Ball Bearings with Snap Ring Grooves

Simplify configuration design:

Bearings with a Flange on the Outer Ring

Some sizes of Deep Groove Ball Bearing Supplier THB stainless steel Deep Groove Ball Bearings have a flange on the outer ring. They:

can be supplied as open and closed bearings.

are relatively easy to axially locate in the housing.

make bearing hole manufacturing easier and more cost-effective, requiring no shaft shoulder.

Matched Bearings

Used when the load capacity of a single bearing is insufficient.

Used when the shaft must be axially located in both directions with a specific axial clearance.

Allow load distribution between bearings when mounted in close proximity without the need for spacers or similar devices.

Matched bearings come in three different configurations:

Tandem Configuration

Used when the load capacity of a single bearing is insufficient.

Have parallel load lines, thus equally distributing radial and axial loads.

Can withstand axial loads in both directions.

Back-to-Back Configuration

Have load lines that separate towards the bearing axis.

Provide a relatively rigid bearing configuration.

Can withstand overturning moments.

Can withstand axial loads in both directions, but each bearing can only withstand axial loads in one direction.

Face-to-Face Configuration

Have load lines that converge towards the bearing axis.

Are less sensitive to misalignment errors but are less rigid than back-to-back configurations.

Can withstand axial loads in both directions, but each bearing can only withstand axial loads in one direction.

English

English