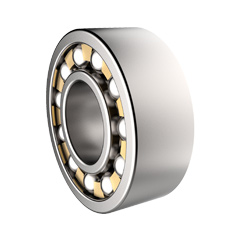

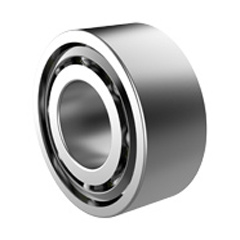

Deep Groove Ball Bearing

Deep groove ball bearing has a wide range of sizes and are the most commonly used roll bearings with simple structure, standardized machining process, reliability, durability and high-cost performance. Deep groove ball bearings can bear axial load in both radial and light axial directions and are easy to install at low maintenance costs.

They have low friction torque and are optimized for low vibration and low noise, which are suitable for high-speed operation.

Applications: electric motors and generators, agriculture, material transportation, industrial gearboxes, food and beverage, industrial pumps, industrial fans, vehicles, etc.

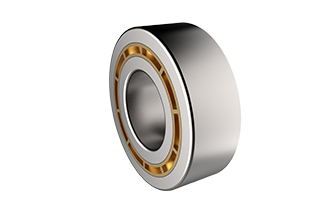

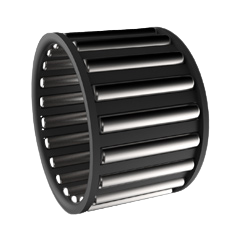

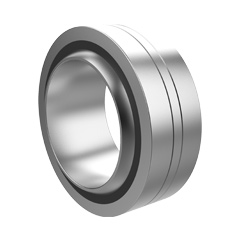

Double Row Deep Groove Ball Bearing

Each of the inner and outer rings has two rows of tracks with circular cross-sections. The rolling body structure is similar to a pair of single-row ball bearings.

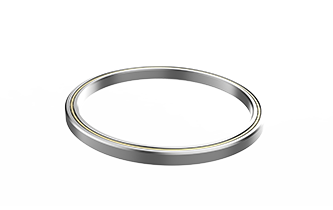

Thin Section Deep Groove Ball Bearing

Thin section deep groove ball bearings are mainly used in space-limited working conditions. Such bearings are available in both open and closed configurations.

Key Features of Deep Groove Ball Bearing

Deep groove ball bearings provided by THB, as one of the most professional deep groove roller bearing suppliers in China, have the features of high radial load, high speed and long service life.

High radial load: The outer ring with high wall thickness can not only withstand high radial load, but also reduce deformation and bending stress when working as a roller.

Withstanding overturning moment: Double-row ball roller bearings can withstand greater overturning moment compared to single-row ball roller bearings.

Long service life: The convex design of the outer ring surface can be greatly improved to cope with the possible inclination of the outer ring on the working track surface, or where the edge stress needs to be minimized.

Relatively high speed capacity.

Angular Contact Ball Bearing vs Deep Groove Ball Bearing

Angular contact ball bearings and deep groove ball bearings have the same structure, which are composed of inner ring, outer ring, rolling elements, and raceways. But these two types of bearings are quite different. Where are the differences?

1. The accuracy is different: the outer raceway surface of angular contact ball bearing is different from that of deep groove ball bearing. The raceways of angular contact ball bearings are not the same high, on one side high and low on the other side. The accuracy of angular contact ball bearings is higher than that of deep groove ball bearings.

2. The load capacity is different: angular contact ball bearings can bear radial and axial forces. Single row angular contact ball bearings can bear radial force while bearing one side's axial force, so single row angular contact ball bearings are generally paired used. Back-to-back, face-to-face arrangement can bear the radial force while bearing the axial force of the double term; and when used in pairs, it can bear double the axial force of one side. Deep groove ball bearings can withstand radial forces, but only a slight axial force.

The rotational speeds of the angular contact ball bearings and deep groove ball bearings are relatively high. The difference between them is mainly due to the different raceway surfaces. The rolling elements of angular contact ball bearings form a contact angle with the raceway surface. According to the different sizes of contact angle which can be divided into 15°, 25°, 40°, etc., the greater the contact angle, the greater the axial force it will bear.

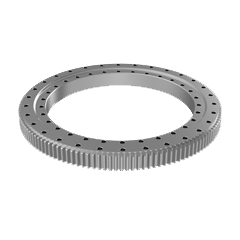

Deep Grove Ball Bearing Types

Deep groove ball bearings are one of the most common type of rolling bearings. The basic deep groove ball bearing consists of an outer ring, an inner ring, a set of steel balls and a set of cages. The deep groove ball bearing type code is 6.

Deep groove ball bearings are mainly used to bear radial load, but also can bear radial load and axial load at the same time. When it only bears radial load, the contact angle is zero. When the deep groove ball bearing has a larger radial clearance, it has the performance of an angular contact bearing and can bear a larger axial load. The friction coefficient of deep groove ball bearings is very small, and the limit speed is also very high, especially in the high-speed operating conditions with moderate axial loads, deep groove ball bearings are superior to thrust ball bearings.

Deep groove ball bearings have a simple structure and are easier to achieve higher manufacturing accuracy than other types. Therefore, they are easy to produce in series and have lower manufacturing costs, and they are extremely common. In addition to the basic type, deep groove ball bearings have various deformation structures, such as deep groove ball bearings with dust cover; deep groove ball bearings with rubber seals; deep groove ball bearings with snap grooves; full complement deep groove ball bearing with filling slots; double row deep groove ball bearing.

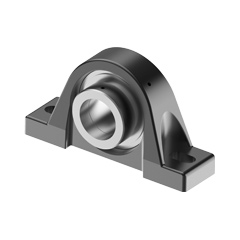

The Installation of Deep Grove Ball Bearing

Method 1: press fit: the inner ring of the deep grove ball bearing and the shaft are tightly matched, and the outer ring and the housing hole are loosely matched, and the bearing can be press-fitted on the shaft by a press, and then the shaft and the bearing put them into the bearing seat hole together. When press-fitting, on the end face of the bearing inner ring, padded an assembly sleeve made of soft metal material (copper or mild steel). The outer ring of the deep grove ball bearing is tightly matched with the hole of the bearing seat. When the fit is loose, the bearing can be pressed into the bearing seat hole first. At this time, the outer diameter of the assembly sleeve should be slightly smaller than the diameter of the seat hole. If the bearing ring is tightly fitted with the shaft and the seat hole, install the inner ring and the outer ring should be pressed into the shaft and the seat hole at the same time, and the structure of the assembly sleeve should be able to compress the end faces of the inner ring and the outer ring at the same time.

Method 2: heating fit: by heating the bearing or bearing seat, using thermal expansion to transform the tight fit into a loose fit. It is a common and labor-saving installation method. This method is suitable for large interference. To install the deep grove ball bearing, put the bearing or separable bearing ring into the oil tank and heat it evenly at 80-100℃, then remove it from the oil and install it on the shaft as soon as possible, in order to prevent the inner ring end face and shaft shoulder from cooling If the fit is not tight, the bearing can be tightened axially after cooling. When the outer ring of the bearing is tightly fitted with the light metal bearing seat, the hot fitting method of heating the bearing seat can be used to avoid scratches on the mating surface. When heating the bearing with an oil tank, there should be a grid at a certain distance from the bottom of the box, or the bearing should be hung with a hook. The bearing cannot be placed on the bottom of the box to prevent sinking impurities from entering the bearing or uneven heating. There must be a thermometer in the oil tank. Strictly control the oil temperature not to exceed 100°C to prevent the occurrence of tempering effects and reduce the hardness of the ferrule.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano