Plain Bearing Definition

Sliding bearing is a bearing that works under sliding friction. Sliding bearings work smoothly, reliably and without noise. Under liquid lubrication conditions, the sliding surfaces are separated by lubricating oil without direct contact, which can greatly reduce friction loss and surface wear, and the oil film also has a certain vibration-absorbing ability, but the starting friction resistance is large. The part of the shaft supported by the bearing is called the journal, and the part that matches the journal is called the bearing bush. In order to improve the friction properties of the bearing surface, the layer of anti-friction material cast on its inner surface is called a bearing lining. The materials of the bearing shell and bearing bush are collectively referred to as sliding bearing materials. Sliding bearing is generally applied in high-speed and light-load conditions.

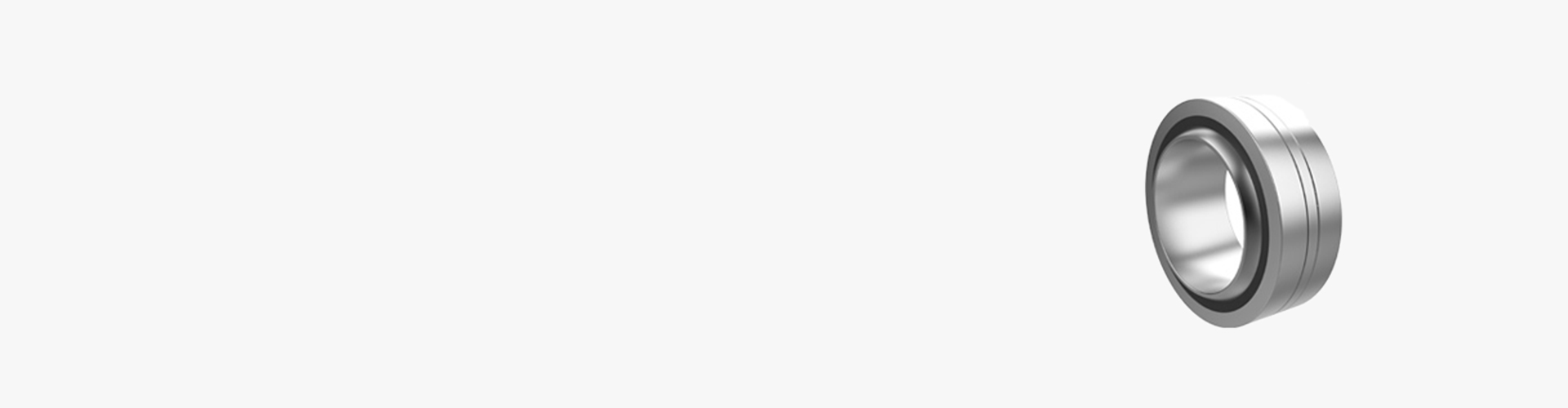

The Features of Spherical Plain Bearing

-

Installation

When assembling the spherical plain bearing series, it is necessary to pay special attention to the position of the outer ring dividing surface. In order to prevent the load from directly acting on the dividing surface, the dividing surface should be maintained at right angles to the matching direction.

-

Loading and unloading

The assembly and disassembly of spherical plain bearings should follow the following principles, that is, the force exerted by assembly and disassembly cannot be transmitted directly through the spherical sliding surface. In addition, auxiliary loading and unloading tools, such as sleeves, disassemblers, etc., should be used to directly and uniformly apply the loading and unloading force exerted by the outside to the matching ferrule, or use auxiliary methods such as heating for unloaded loading and unloading.

-

Operating temperature

The allowable working temperature of the spherical plain bearing is mainly determined by the matching materials between the bearing sliding surfaces, especially the plastic sliding surface of the self-lubricating spherical plain bearing, its load-carrying capacity will decrease at high temperature. For example, when the sliding surface material of lubricated spherical plain bearing is steel/steel, the allowable working temperature depends on the allowable working temperature of the lubricant. But for all lubricated and self-lubricating spherical plain bearings, they can be used in the temperature range of -30℃~+80℃, and maintain the correct bearing capacity.

English

English