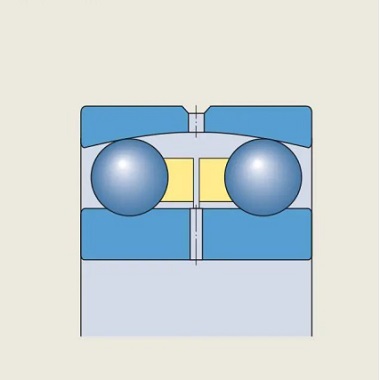

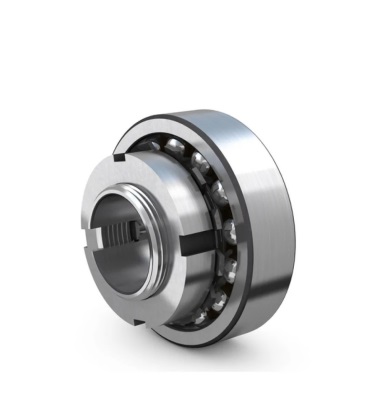

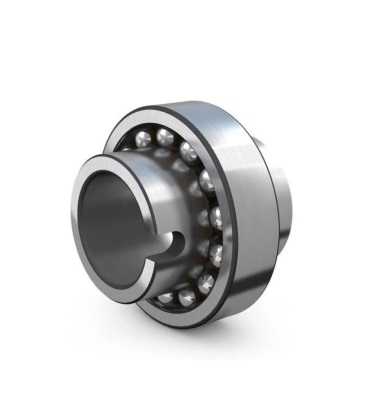

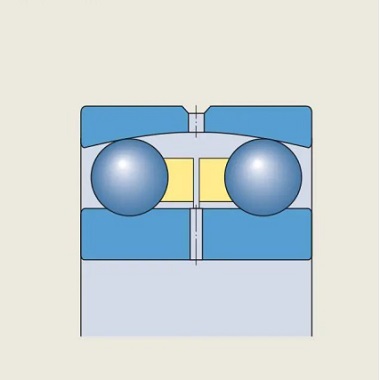

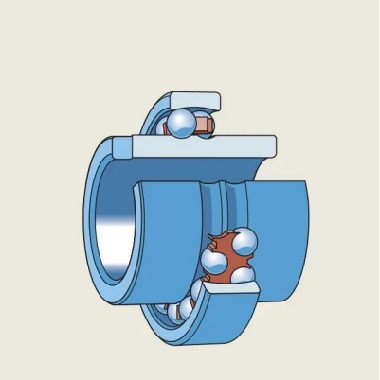

Self-aligning Bearings have two rows of balls, with a spherical raceway on the outer ring and two deep groove raceways on the inner ring. Self-aligning Bearings can be either open bearings or self-sealed Self-aligning Bearings. These bearings allow for significant misalignment between the shaft and the bearing seat, such as misalignments caused by shaft deflection.

Self-aligning Bearings Features

Accommodates static and dynamic alignment errors

Like spherical roller bearings or CARB toroidal roller bearings, these bearings also have self-aligning capabilities.

Excellent high-speed performance

Compared to any other type of rolling bearing, Self-aligning Bearings generate less friction, resulting in lower temperature rise even under high-speed operation.

Minimal maintenance requirement

The low heat generation leads to a smaller temperature rise, thus extending bearing service life and maintenance intervals.

Low friction

The larger clearance fit between the rolling elements and the outer ring reduces friction and friction heat.

Excellent light load performance

Self-aligning Bearings have a low minimum load requirement.

Low noise

In applications like fans, Self-aligning Bearings can reduce noise and vibration levels.

Types of Self-aligning Bearings

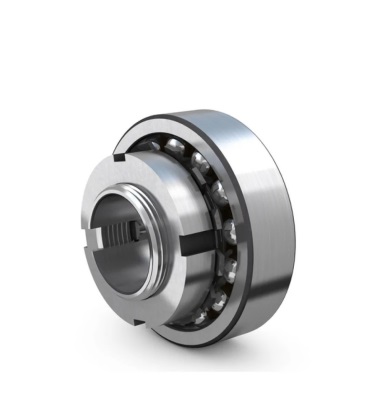

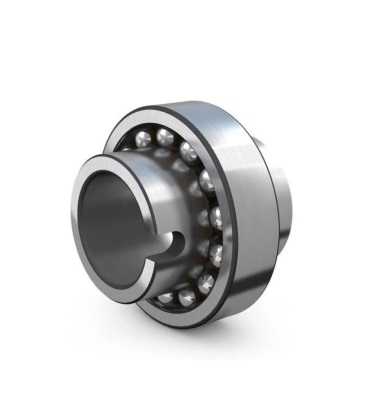

Open Self-aligning Bearings

-With cylindrical bore

Bearings with locking devices on an adapter sleeve

- With tapered bore,e.g., used with an adapter sleeve

- With extended inner ring

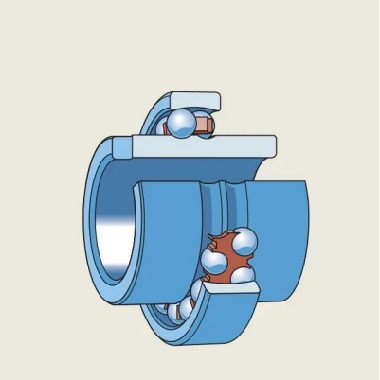

Sealed Self-aligning Bearings

- With cylindrical bore

- With tapered bore,e.g., used with an adapter sleeve

Compared to the open design, sealed Self-aligning Bearings allow for reduced angular misalignment.

Large Self-aligning Bearings

All have an annular lubrication groove on the outer ring and

- Three equally spaced lubrication holes on the outer ring

- Six equally spaced lubrication holes on the inner ring

Can be used in any application demanding low friction and high load carrying capacity,(e.g., in the paper industry).

Bearings with extended inner ring

Designed for commercial grade shafting applications with less demanding requirements.

Installing Self-aligning Bearings

Installing cylindrical bore bearings:

Separatable bearings

For separable bearings, because the inner and outer rings can be installed separately, the installation process is generally simpler, especially for bearings where both the inner and outer rings are interference fits. When installing the shaft and inner ring assembly into a housing fitted with the outer ring, ensure alignment to avoid scratching the raceways and rolling elements. For cylindrical or needle bearings with inner rings carrying edges only on one side or without carrying edges, it is recommended to use a guide sleeve.

Non-separable bearings

When installing non-separable bearings, the bearing ring requiring an interference fit is usually installed first.

Cold mounting

When installing small bearings where the fit is not too tight, a hammer can be used to lightly tap the bearing installation tool to move the bearing into the desired position. This tool can exert installation force on the center position.

If both the inner and outer rings of the bearing need to be installed on the shaft and into the housing simultaneously, ensure the same pressure is applied to both the inner and outer rings and that the contact surfaces of the installation tool are in the same plane. If feasible, use a bearing mounting tool.

Installing tapered bore bearings:

Self-aligning ball Bearings with tapered bores can be installed using one of the following methods:

Feeling the reduction in clearance by rotating and turning the outer ring.

- Suitable for bearings with normal radial clearance groups(not suitable for sealed bearings).

- If the outer ring can be turned easily but has slight resistance when tilted sideways, the bearing has reached the required reduction in clearance.

Measuring the locking angle of the locknut.

Measuring axial displacement distance.

English

English