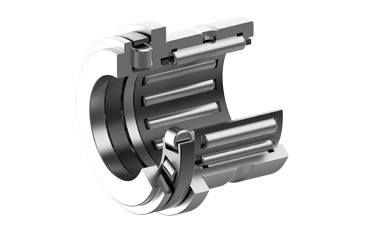

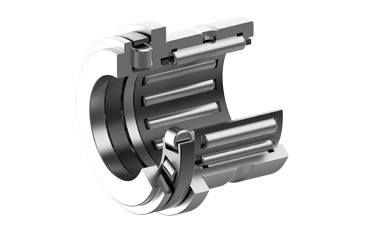

Characteristics of Combined Needle Roller Bearings

Combined needle roller bearings belong to a type of rolling bearing, composed of inner and outer conical surfaces and needle rollers. When a load is applied between the inner and outer rings, the needle rollers roll circumferentially, thereby reducing the friction between the inner and outer rings. Its characteristics include high load capacity, high speed, and low friction. Combined needle roller bearings can withstand both radial and axial loads, making them suitable for high-speed, high-precision rotating equipment.

Application Scenarios of Combined Needle Roller Bearings

Combined needle roller bearings are mainly suitable for applications requiring high speed and precision. Due to their special structural design, these bearings can reduce internal friction and improve rotational accuracy, thereby meeting the requirements of various precision machinery.

In the aerospace field, combined needle roller bearings are widely used due to their excellent performance and stability. For example, certain satellites' transmitters and receivers require such high-precision bearings to ensure their normal operation.

Additionally, in the automotive manufacturing industry, with the development of new energy vehicles and the continuous pursuit of energy conservation and emission reduction, electric vehicles demand higher performance from motors. Combined needle roller bearings, with their stability and longevity under high-speed operation, have become an important component of the drive system, providing strong technical support for the electrification of vehicles.

Installation Method of Combined Needle Roller Bearings

Confirm Installation Position

Before installing the combined needle roller bearing, confirm that its installation position is correct and perform necessary cleaning.

Lubrication

When installing the combined needle roller bearing, apply the appropriate lubricant to reduce friction and extend its service life.

Installation

Gently place the combined needle roller bearing into the installation hole, then tap it gently with a hand or light hammer to ensure it enters the installation hole evenly until it reaches the bottom.

Installation of Bearing Seat

When installing the combined needle roller bearing, pay attention to the position and direction of the seat to ensure it fits well with the bearing.

Precautions for Combined Needle Roller Bearings

When using combined needle roller bearings, pay attention to the usage environment, avoiding excessive vibration and high temperature that could affect the bearing.

When lubricating combined needle roller bearings, choose the appropriate lubricant and lubricate according to the specified cycle and amount.

When installing combined needle roller bearings, be mindful of the size and shape of the installation hole to ensure the bearing can fully enter the hole.

When operating combined needle roller bearings, regularly check the operating condition of the bearing, and promptly identify and address issues to ensure its normal operation and service life.

In conclusion, combined needle roller bearings are a commonly used type of bearing. With their unique structure and excellent performance characteristics, they are widely applied in mechanical equipment across various industrial fields, particularly in scenarios demanding high speed, high precision, and load capacity. The usage methods and precautions for combined needle roller bearings are crucial for ensuring the normal operation of equipment and extending the bearing's service life.

English

English