When it comes to industrial manufacturing, efficiency and reliability are crucial factors to consider. This is why choosing the right components for your machinery is essential. One such component that plays a significant role in the smooth functioning of industrial equipment is the plummer bearing.

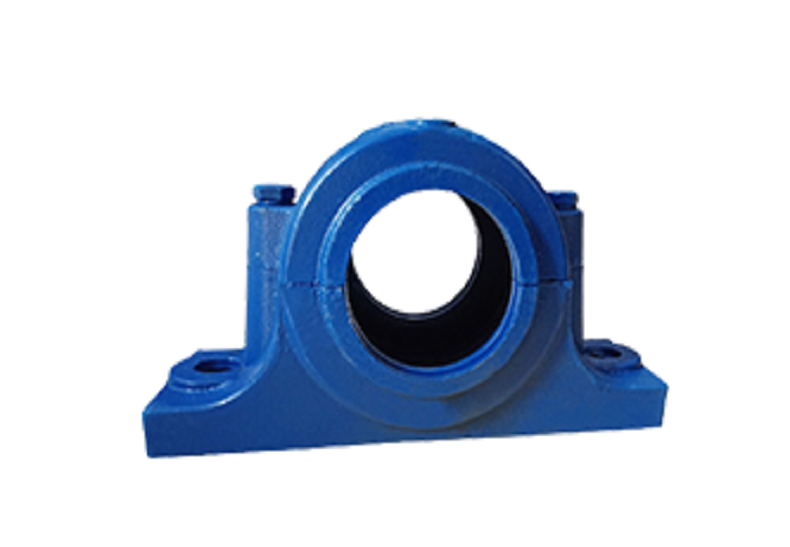

Plummer bearings, also known as pillow block bearings, are a type of rolling-element bearing commonly used in various industrial applications. These bearings are housed in a support, or plummer block, which provides the necessary support for the bearing as well as an easy way to mount it onto a machine.

The versatility of plummer bearings makes them an ideal choice for a wide range of industrial manufacturing processes. Let's take a closer look at how plummer bearings are used and why they are so essential in the industrial sector.

Versatile Design

One of the main reasons why plummer bearings are so popular in industrial manufacturing is their versatile design. These bearings come in various sizes and configurations, making them suitable for different types of machines and equipment. Whether you need a compact bearing for a small machine or a heavy-duty bearing for a large industrial application, plummer bearings can be customized to meet your specific requirements.

Additionally, plummer bearings are available in different materials, including stainless steel, cast iron, and thermoplastic, allowing manufacturers to choose the best option for their particular needs. This versatility in design makes plummer bearings a versatile and reliable choice for various industrial applications.

Easy Installation and Maintenance

Another advantage of using plummer bearings in industrial manufacturing is their ease of installation and maintenance. These bearings are designed to be easily mounted onto a machine, reducing downtime and increasing overall efficiency. Additionally, plummer bearings are self-aligning, which means they can compensate for any misalignment or shaft deflection, ensuring smooth and trouble-free operation.

Furthermore, plummer bearings are designed for easy maintenance, with features such as grease fittings and removable seals that allow for quick and convenient servicing. This makes plummer bearings a cost-effective and practical choice for industrial manufacturers looking to optimize their production processes.

High Load Capacity

Plummer bearings are known for their high load capacity, making them suitable for heavy-duty industrial applications. These bearings can withstand significant radial and axial loads, providing reliable support for rotating machinery and equipment. Whether you are operating a conveyor belt, a gearbox, or a fan, plummer bearings can handle the demanding conditions of industrial manufacturing, ensuring consistent performance and longevity.

Wide Range of Applications

Due to their versatility and reliability, plummer bearings are used in a wide range of industrial applications across various sectors. From mining and construction to agriculture and food processing, plummer bearings play a crucial role in keeping machinery and equipment running smoothly. Some common applications of plummer bearings include conveyor systems, fans and blowers, pumps, and compressors, among others.

In conclusion, plummer bearings are a versatile and essential component in industrial manufacturing. Their reliable performance, ease of installation and maintenance, high load capacity, and wide range of applications make them a valuable asset for any industrial operation. Whether you are looking to optimize your production processes or improve the performance of your machinery, plummer bearings are a reliable choice that can help you achieve your manufacturing goals.

English

English