No matter which type of device, the lubricant oil leakage of bearings is a big problem. After the lubricant oil and grease leak, they will remain on the surface of the bearing. When the surface of the bearing is exposed to dust or dirt, it will corrode the surface of the bearing and reduce the service life. Let's take a look at the reasons and treatment methods for the oil leakage of the slewing ring bearing.

Reasons for oil leakage of the slewing ring bearing

Frequent lubricant filling

The lubricant for the slewing ring bearing should be filled every 150-250 hours. The manufacturer's maintenance cycle is 250 hours, but it can be appropriately shortened according to the working intensity and frequency of the turntable. If it is filled too frequently, it will cause a large amount of lubricant leakage.

The lubricant becomes thin

Check whether the hydraulic oil or gear oil of the turntable motor has flowed into the cavity of the turntable gear ring. If this kind of leakage occurs, after opening the inspection cover of the lubricant of the turntable gear ring, it will be found that the lubricant has become thin due to the mixing with the hydraulic oil or gear oil.

Incorrect use of lubricants

Because the lubricant added to the original equipment may be incorrect, the temperature of the slewing ring bearing or turntable gear ring may cause the lubricant to become thin. If the thin lubricant is pushed to the upper surface of the inner gear ring by the active gear of the turntable motor during the meshing process, it will flow into the bearing cavity through the inner oil seal, and then drip out from the outer oil seal.

Damage to the outer oil seal

Carefully check the turntable oil seal to determine whether it is a local or segmental leakage or uniform peripheral leakage, and whether there is any missing part in the entire turntable oil seal.

Loosening of the outer oil seal

The outer oil seal should be relatively fixed with the sealing groove of the lower frame. It should be observed when the excavator is turning. If the oil seal also rotates when the equipment is turning, it means that the existing oil seal has loosened in the sealing groove and must be replaced. This method is risky, so pay attention to safety, but it is one of the important methods to check whether the turntable oil seal is really sealed.

Damage to the inner oil seal

Open the inspection cover of the turntable gear ring lubricant and check whether there is a large reduction in grease or whether there are pieces of broken oil seal in the gear ring oil chamber. If the lubricant has decreased significantly, it indicates that the lubricant has leaked out.

Excessive clearance between bearings

If there is abnormal noise or instability during the turntable movement of the equipment, it may be that the clearance between the bearings is too large and uneven, which causes the oil to be squeezed out from the outer oil seal during the rotation of the bearing. After knowing the reason for the oil leakage of the slewing ring bearing, let's take a look at how to deal with the problem of grease leakage.

Treatment methods for oil leakage of the slewing ring bearing

If it is caused by sealing, the old seal should be removed, the sealing slot should be cleaned with diesel or gasoline, and the new seal should be completely inserted into the sealing slot. It should be noted that after the sealing strip becomes a circular shape, there is a joint that needs to be glued together with double-sided adhesive.

If the leaking of the turntable motor causes the lubricant to deteriorate, the turntable motor needs to be repaired to solve the problem fundamentally, and then the lubricant of the entire turntable gear ring needs to be replaced.

If the leakage is caused by improper use of lubricants, all the lubricants of the turntable gear ring should be replaced. At the same time, the same brand of lubricants should be used in the bearing cavity. Lithium-molybdenum-based lubricants can be used, which will not decrease viscosity at high temperatures.

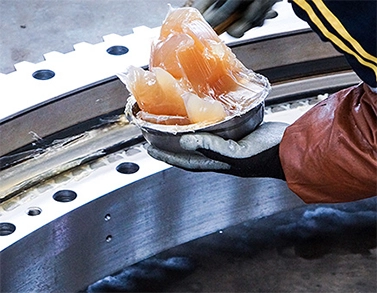

Control the maintenance cycle of the slewing ring bearing correctly. The lubricant should be filled every 150-250 hours of operation. The lubricant can be filled multiple times. The lubricant should be filled once every 90° of rotation of the excavator. The filling amount should be limited to the overflow of the lubricant from the outer oil seal.

If there are no problems elsewhere, check whether the slewing ring bearing is damaged. If the slewing ring bearing is damaged, the entire slewing ring bearing needs to be replaced.

After knowing the reasons for the oil leakage of the slewing ring bearing, preventive measures and maintenance can be taken against these reasons. Of course, the slewing ring bearing is also a type of bearing. Different bearings encounter lubricant oil leakage, and different methods can be used to deal with different lubricant oil leakage situations.

English

English