When it comes to choosing a needle sleeve bearing for your application, there are a few key factors to consider. From load capacity to operating temperature, the right bearing can make all the difference in the performance and longevity of your equipment. In this blog, we will discuss the importance of selecting the right needle sleeve bearing and provide some tips for finding the perfect fit for your needs.

Understanding needle sleeve bearings

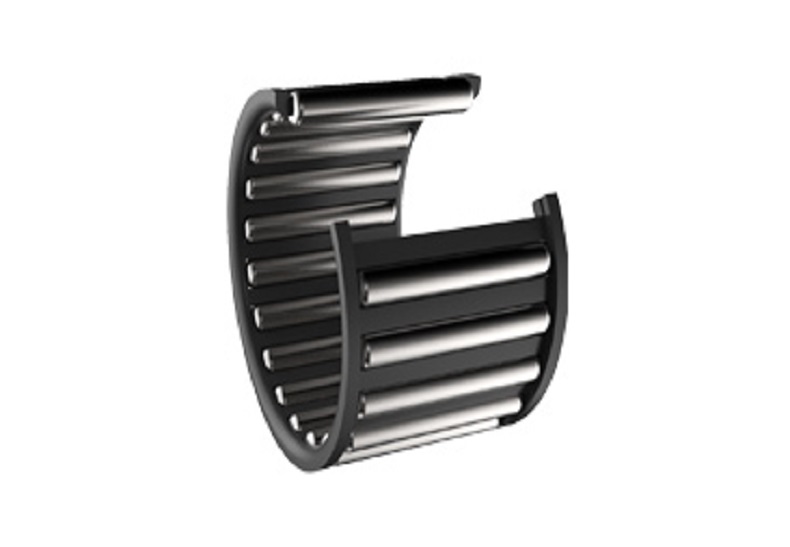

Needle sleeve bearings, also known as needle roller bearings, are a type of roller bearing that uses thin, cylindrical rollers instead of balls to reduce friction and support heavy loads. This design allows for a higher load capacity and better performance in high-speed applications compared to ball bearings. Needle sleeve bearings are commonly used in industrial and automotive applications where space is limited and heavy loads need to be supported.

Factors to consider when selecting a needle sleeve bearing

Load capacity: One of the most important factors to consider when selecting a needle sleeve bearing is the load capacity. You will need to determine the maximum load that the bearing will need to support in your application and choose a bearing that can handle that load. THB Bearings offers a wide range of needle sleeve bearings with varying load capacities to suit different needs.

Operating temperature: Another important factor to consider is the operating temperature of your application. Needle sleeve bearings can operate in a wide range of temperatures, but it is essential to choose a bearing that can withstand the heat or cold that your equipment will be exposed to. THB Bearings offers needle sleeve bearings that are designed to perform in extreme temperature conditions.

Size and dimensions: The size and dimensions of the needle sleeve bearing are also crucial factors to consider. You will need to choose a bearing that fits the space constraints of your equipment while still providing the necessary load capacity. THB Bearings offers a variety of needle sleeve bearings in different sizes and configurations to meet the needs of various applications.

Lubrication: Proper lubrication is essential for the performance and longevity of a needle sleeve bearing. THB Bearings offers needle sleeve bearings that are pre-lubricated with high-quality grease to reduce friction and wear, extending the bearing's lifespan and improving performance.

Finding the right needle sleeve bearing for your application

With so many options to choose from, finding the right needle sleeve bearing for your application can seem like a daunting task. However, by considering the factors mentioned above and working with a trusted supplier like THB Bearings, you can ensure that you get the perfect bearing for your needs. THB Bearings offers a wide range of needle sleeve bearings designed to meet the demands of various industries and applications. Whether you need a bearing for a high-speed automotive application or a heavy-duty industrial machine, THB Bearings has you covered.

In conclusion, selecting the right needle sleeve bearing for your application is crucial for achieving optimal performance and longevity. By considering factors such as load capacity, operating temperature, size and dimensions, and lubrication, you can find the perfect bearing for your needs. THB Bearings offers a wide range of needle sleeve bearings designed to meet the demands of various industries and applications, making it easy to find the ideal solution for your equipment.

English

English