THB understands the needs and expectations of customers when looking for partners. In this particular case, the following three requirements are the core and critical demands of the client's equipment:

ACCURATE ROTATIONAL POSITIONING;

LITTLE TO NO COMMISSIONING/OVER 20,000 OSCILLATIONS;

SIMPLE ASSEMBLY

These demands will ensure the excellent performance and reliability of the client's equipment.

Based on these requirements, THB provides the following solution for the customer:

THB Solution

Final Model Selection

THB selects each precision crossed roller bearing based on the specific operating conditions and requirements of customer's equipment.

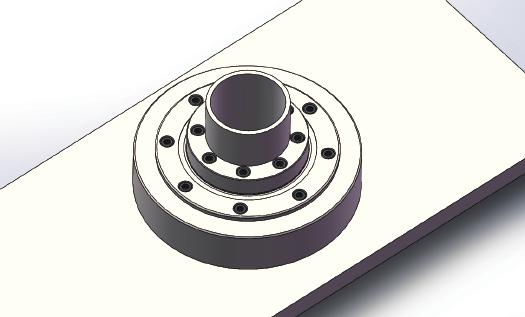

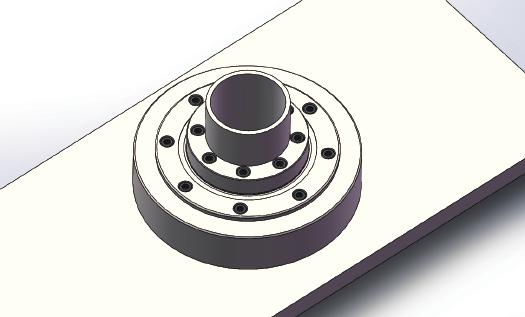

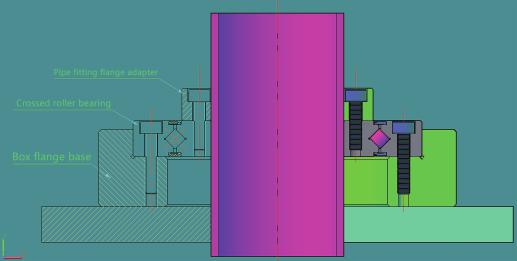

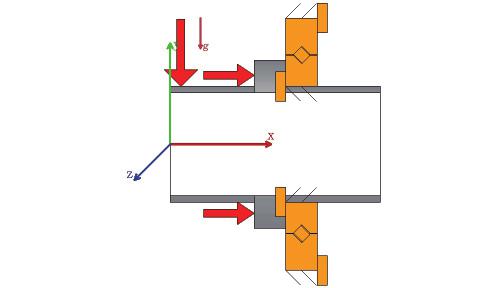

Fig. 1: Post-optimization assembly schematic

PRODUCT DESIGN OPTIMIZATION

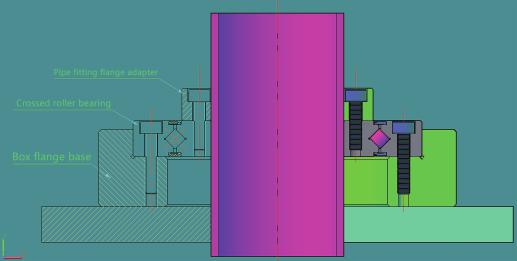

01 To meet customer requirements for easy assembly, inner and outer rings with mounting holes are selected so as to ensure a direct, form-fitting connection between the pedestal and flange.

02 A preload negative clearance design is utilized, which is able to provide stable preload torque during rotation to ensure proper operation.

Fig. 2: Post-optimization assembly schematic

SOLUTION VERIFICATION

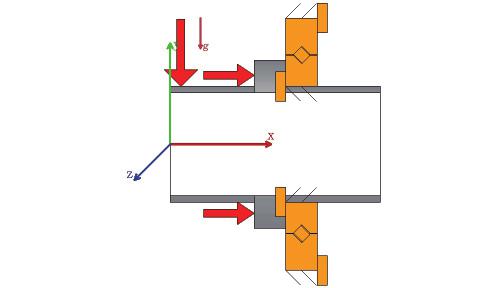

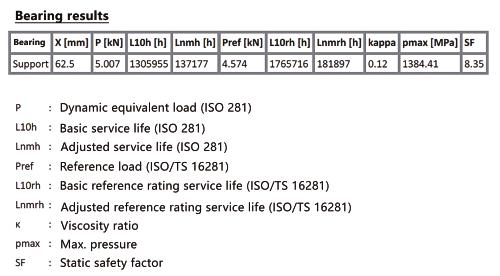

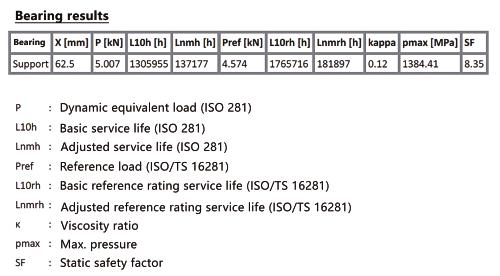

Verification with special software: A results-oriented analysis on bearing service life and static safety is carried out by using bearing-specific service life analysis software, proving that both service life and static safety factor meet customer requirements.

Fig. 3: Bearing assembly and stress schematic

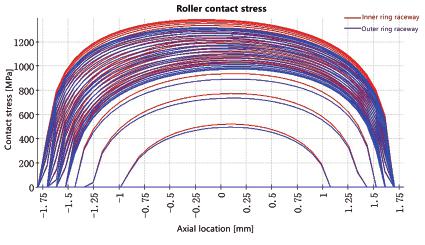

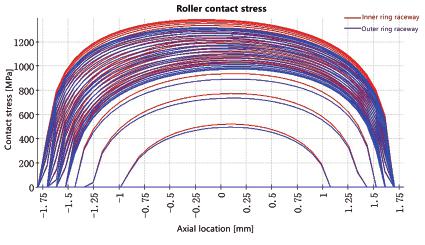

Fig. 4: Roller contact stress

Fig. 5: Bearing service life and static safety factor calculation results

EXPECTED BENEFITS FROM THIS SOLUTION

Based on customer feedback, our optimized product design can contribute to a significant reduction of 50% in assembly time. Additionally, our product offers steady rotational precision at 4.8~5.2N·m and pipe fitting end tolerances within 0.3mm, which fully meets our customers' requirements. Furthermore, even after being subjected to more than 50,000 oscillations, our product's precision continues to remain within the limits set by its original design.

English

English