Water can also be turned into a very sharp cutting tool, which is the water jet.

Water jet, also known as water cutting, its real name is high pressure water jet cutting technology. Since the 1980s, water jet cutting has been used in industrial production. Its biggest feature is that it can cut any material at one time with any curve.

Because it needs to make a one-shot cut, "positioning" is critical to the use of waterjets.

1. Difficulties troubled by user A of waterjet equipment

Basic conditions

Reciprocating frequency 70-80 times/min, reciprocating stroke 200mm;

The maximum speed is 2000RPM, and the maximum axial load is 10000N.

Under such conditions, the axial movement of the ball screw is more than 2mm, and the positioning accuracy of the water jet for normal operation needs to be at least 0.05mm. The play value of 2mm seriously affects the positioning of the water jet in operation.

This problem made Company A distressed. He also tried to change the bearing type, but it quickly became too hot during work and could not be used.

Company A tried to consult with THB, hoping that THB Company would help him find the cause of the problem.

2. THB technical service experts explore the cause of the problem

"The truth of the problem is always on the scene". Through repeated research on the product design structure and working conditions, THB found that the equipment has two links that can be optimized:

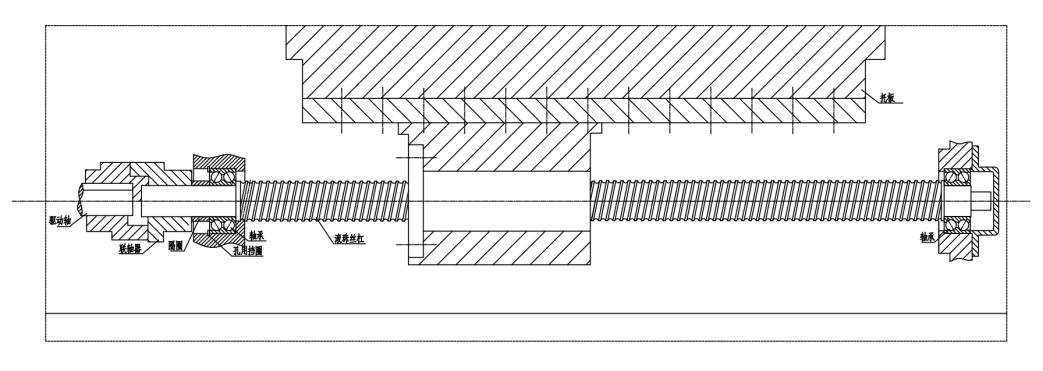

Product positioning form:

Company A currently adopts a double-positioning structure at both ends, in which the inner ring end face of the motor drive end on one side is in direct contact with the coupling through the spacer ring, which also leads to the direct action of the force when the lead screw is subjected to the axial force on this side. In the coupling, the structure of the coupling determines that there is a certain gap in the axial direction, so that the axial direction does not form a strong enough rigid support for the lead screw, which leads to the movement of the lead screw.

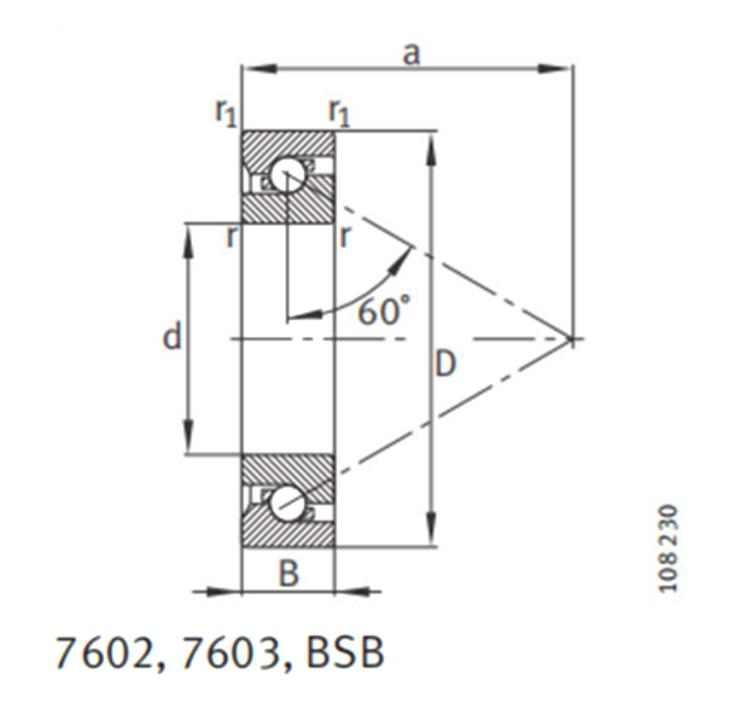

Bearing selection:

At present, double row angular contact ball bearings are used on both sides. The axial clearance of this type of standard product is 9-29um in the unloaded state, and the average axial clearance is 19um.

When the lead screw reciprocates left and right, the direction of the bearing load is changed, which will cause axial movement:

1) The unavoidable axial clearance will cause axial movement;

2) The abnormal movement of the rolling elements in the raceway during the axial reciprocating motion will also cause accelerated wear and fatigue of the bearing.

This will ultimately affect its positioning accuracy and greatly shorten the bearing life, which seriously affects the normal use of the water jet.

Click here to learn more about the selection of bearing type.

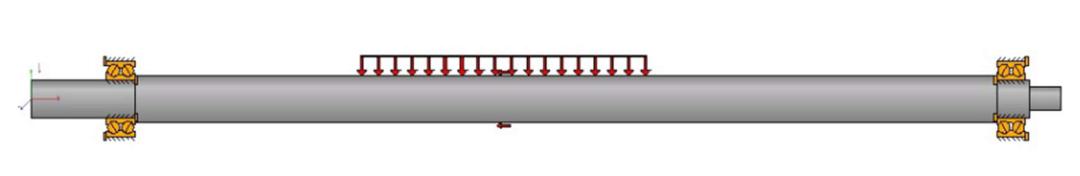

Simulation analysis:

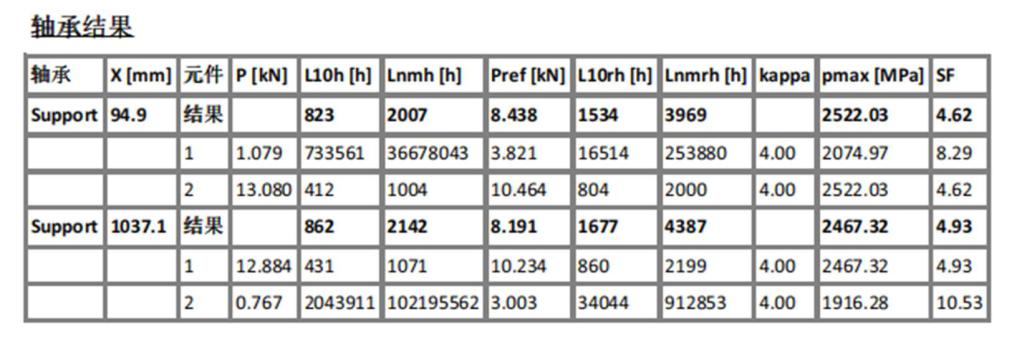

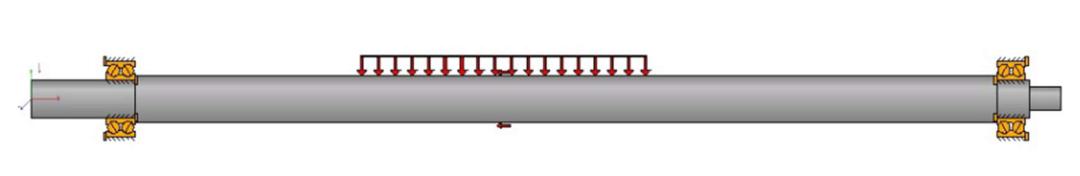

THB simulates the actual working conditions through professional bearing design software, and analyzes the following:

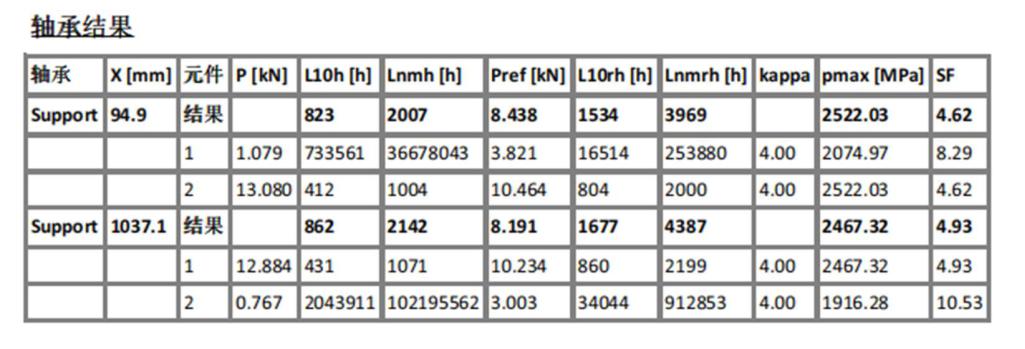

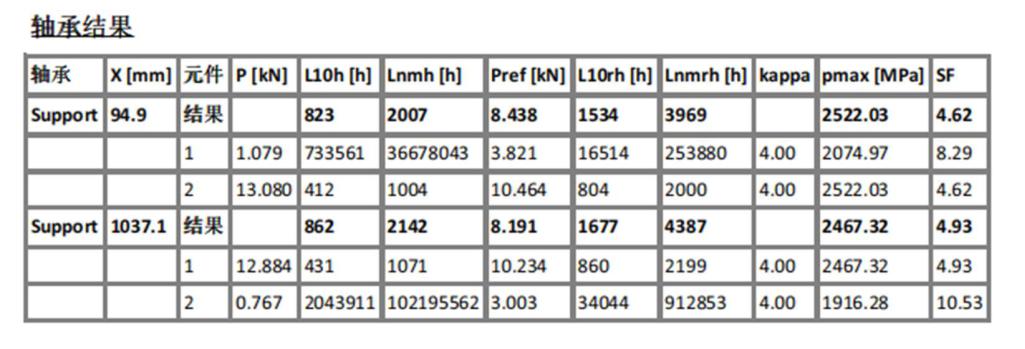

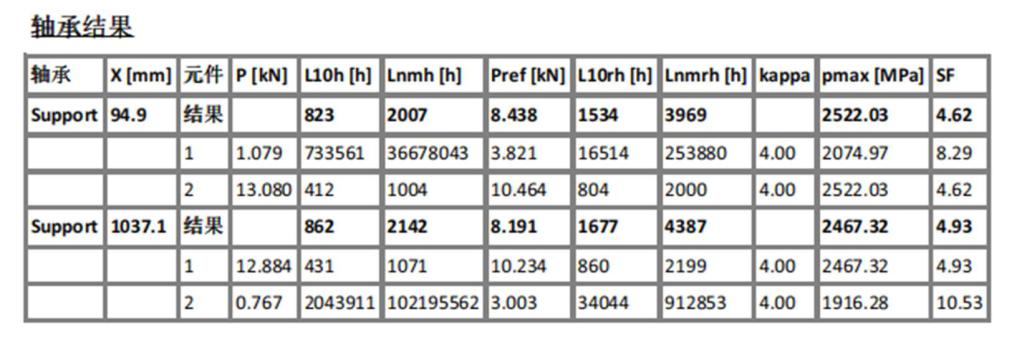

According to the products originally selected by the customer, the estimated life time of the bearing is 823 hours to 862 hours, which is far lower than the life requirement of Company A for the stable operation of the products.

3. THB provides a "tailor-made" solution

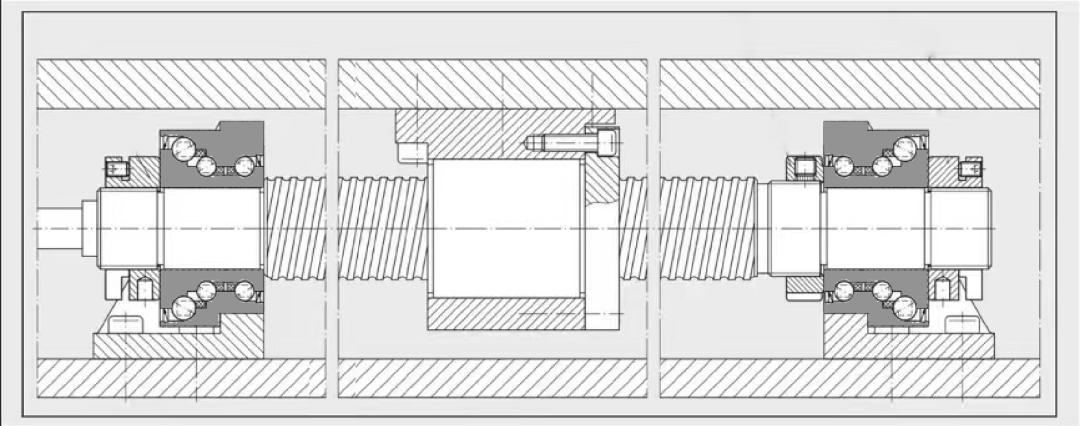

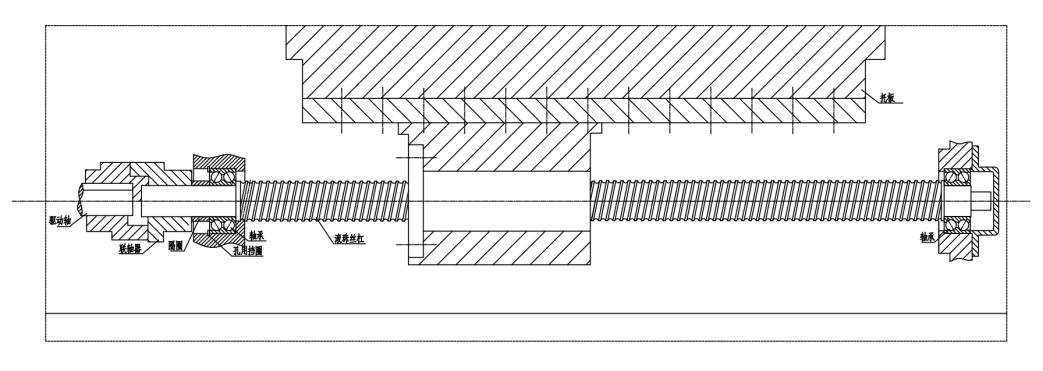

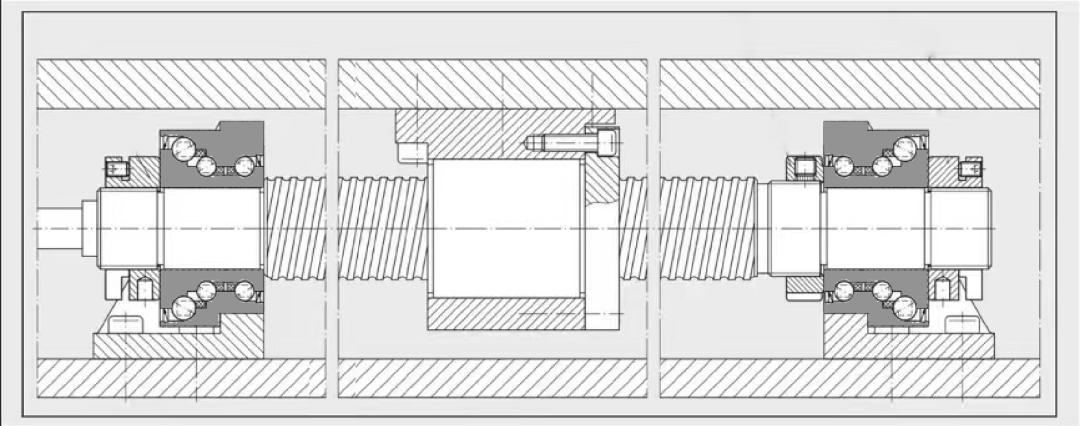

A more rigid form of product positioning:

The axial rigid positioning of the screw is the first core problem to be solved. THB recommends a set of positioning forms that ensure sufficient rigid support in the axial direction (below).

The core advantages of this positioning form are:

● The left and right sides are respectively equipped with high-rigidity ball screw special bearings, and the axial force in two directions is borne by two sets of angular contact ball bearings which mainly bear the axial load of each side bearing. Another group of angular contact ball bearings mainly bear small radial loads.

● The preload configuration of the bearing, plus the rigid preload of the shaft shoulders and retaining rings at the left and right ends, can eliminate the axial clearance during the operation of the ball screw.

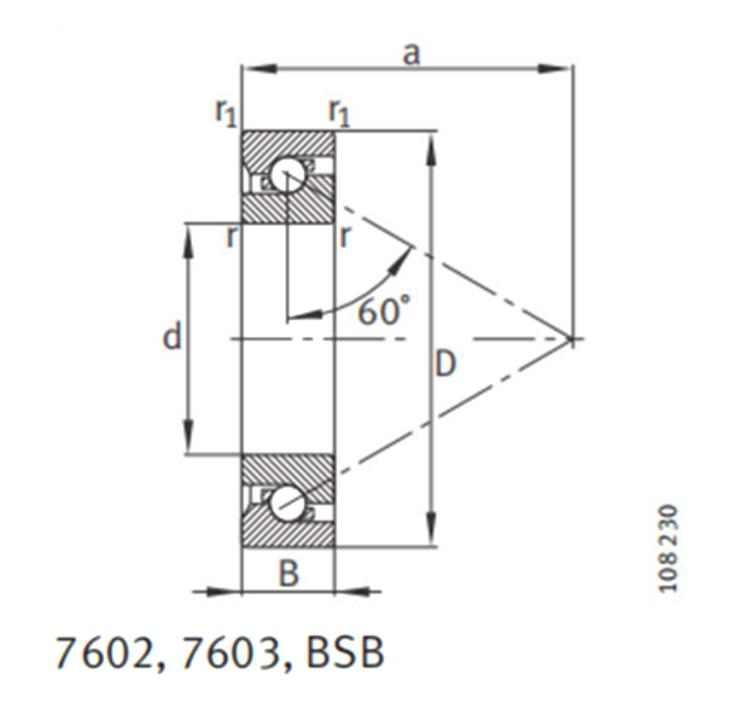

More suitable bearing selection:

It is recommended that customers choose THB ball screw special support bearings and use them in back-to-back pairs. At the same time, it can be combined with the space size under the working conditions to choose the same type with the diameter and width of the bearing seat increased, so that the service life of the bearing can be better extended.

Effect comparison

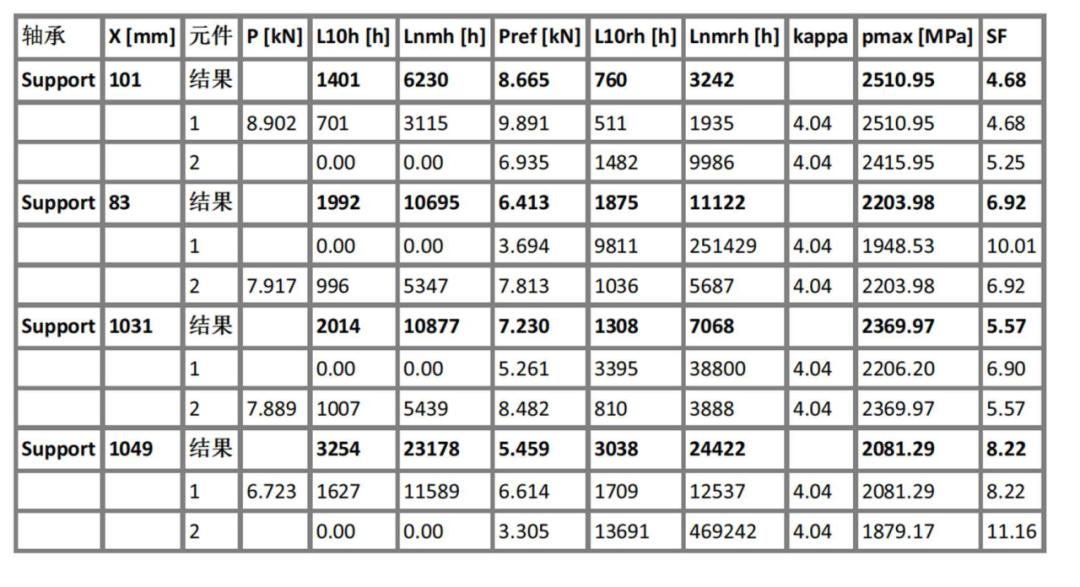

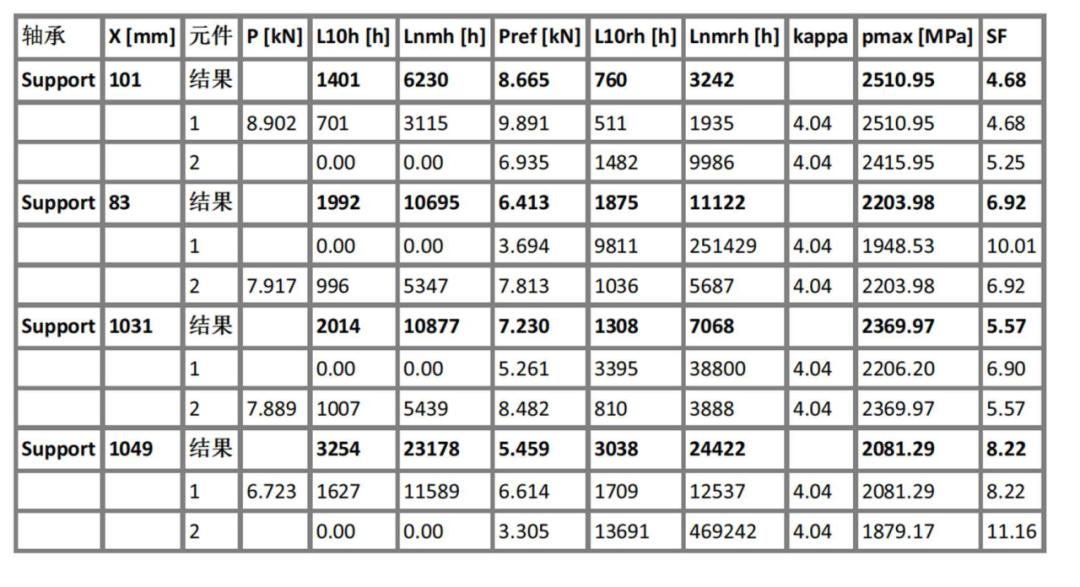

Through professional bearing analysis software, the comparison data of bearing life expectancy simulated according to working conditions are as follows:

823 hours-862 hours VS 1401 hours-3254 hours

It can be seen that the estimated service life of the bearing is up to 3.77 times that of the previous one, which well meets the needs of Company A.

Estimated bearing life under original design:

Estimated bearing life after THB solution optimization:

English

English