Cam indexers are widely used in the field of machine automation. With the rapid development of Industry 4.0 and automation, there is an increasing demand for cam indexers, of which CNC machining centres are typical representatives.

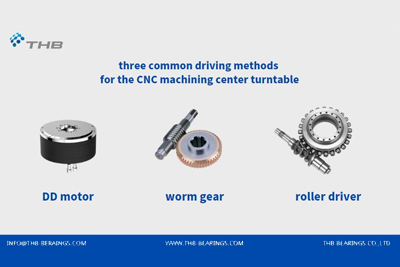

Different mechanisms of rotary tables

DD motor

Worm gear

Cam indexer

The cam indexer stands out for its exceptional processing efficiency, particularly when operating under light to medium loads. It offers an ideal balance between processing accuracy and longevity.

As a result, it has found widespread application in CNC rotary tables across various industries, including semiconductors, automobiles, and 3C . This versatility and impressive performance have garnered increasing market recognition and demand.

How to achieve high positioning accuracy and repeatability of cam indexers in CNC rotary tables?

Through the perfect engagement of the cam curve and the outer ring of the cam follower, the cam roller mechanism is always in a pre-pressure state, whether in forward or reverse rotation or at a standstill, perfectly eliminating backlash, thus ensuring excellent working accuracy and efficiency, effectively avoiding the loss of internal parts and achieving high positioning accuracy and high repeatability in the machined state.

One of the core components of a cam indexer is the bearing, which is essential for good performance. We recommend cam followers, which are optimized for the actual operating requirements and focus on a number of core indicators: Outer ring/shaft raceway roughness, Outer ring/shaft roundness, Outer ring/shaft concentricity, etc.

When selecting cam follower, the following tips will help your cam indexers run better.

Selecting the proper bearing structure - floating/fixed

Selecting the appropriate outer ring to ensure better engagement

Selecting the proper mounting method

Selecting the proper tolerance - interference fit/transition fit / clearance fit

English

English