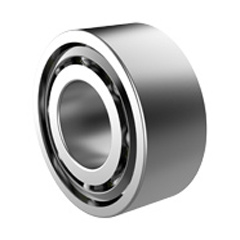

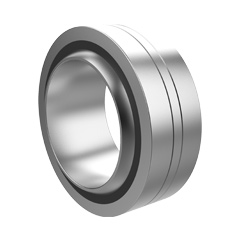

Angular Contact Ball Bearing Assembly Method and Protrusion Measurement Method

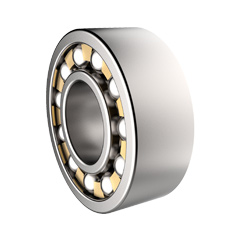

In the machinery industry, two or more angular contact ball bearings of the same type are commonly used in duplex and multi-unit bearings. When the angular contact ball bearing is assembled and used, a certain pre-deformation is generated between the bearing rolling element and the inner and outer ring raceways by applying a load to increase the rigidity of the bearing, improve the rotation accuracy of the shaft, reduce the vibration of the shaft, prolong the service life of the bearing. When the angular contact ball bearings specially designed and manufactured by the manufacturer are assembled, the end face protrusion of a single set of bearings should be measured according to the specified preload, and then assembled according to the standard provisions of "Technical Conditions for Angular Contact Bearings of Rolling Bearings". The user can obtain the predetermined axial clearance and load without using the adjusting shim. For the measurement of the protrusion of the assembled angular contact ball bearing, different methods have been used in different production conditions.

Ⅰ. Angular contact ball bearing assembly method

1. Assembly method

According to the different end faces of the assembled bearings that are close to each other under the action of preload, there are three arrangements and combinations of angular contact ball bearings assembled in pairs. The analysis of the angular contact ball bearing combination and measurement method in pairs is suitable for multi-unit bearings.

2. The assembly process

(1) The inner and outer rings of a single angular contact ball bearing are accepted, cleaned and sorted into the matching process.

(2) When matching a single angular contact ball bearing assembled, it must be pre-matched first. Before the bearing is assembled, add as many steel ball sleeves as possible, and use the measuring accessory to divide the ball. In the matching state, use the load measurement method. Measure the protrusion of a single bearing, and then specify the grinding amount of the end face to be ground according to the assembly requirements, so that the protrusion of the bearing matches each other.

(3) Combine the angular contact ball bearing jacket with other accessories after heating. Wash after combination.

(4) Assembled complete sets of angular contact ball bearings should be measured and recorded according to the preload specified by the finished product, and the finished product inspection and contact angle should be measured and recorded according to the technical requirements of the finished product, and then press the "combination angle". Contact Ball Bearing Specifications" for assembly. After inspection and acceptance of finished products, oiled packaging will be put into storage.

Ⅱ. Measuring method of protrusion of angular contact ball bearing

The protrusion of an angular contact ball bearing refers to the distance that the end face of the inner ring protrudes from the end face of the outer ring at the same end face of the bearing after preloading a single bearing. When the end face of the inner circle is convex, the convex amount is "+" value, and when it is concave, it is "-" value. The protrusion of angular contact ball bearings is an important parameter that affects the performance of the bearing. The measurement of the protrusion value is a necessary procedure in the assembly process, and special instruments are required for measurement. For different types of assembled bearings, there may be different measurement methods for protrusion under different conditions. Usually, the protrusion of angular contact ball bearings is measured as follows.

1. Pneumatic pressure measurement

Turn on the air source, close the power supply, adjust each air circuit element according to the required working state, put the reference piece into the mandrel and enter the measurement position, apply the required load, and after adjusting the reference value of the measuring table, remove the reference piece; Install the bearing to be tested into the mandrel, locate the reference end face of the outer ring, and apply the specified axial force (that is, the measurement load) on the lower end face of the inner ring; measure the relative height difference between the non-reference end of the inner ring and the reference end face of the outer ring, and measure the maximum and minimum protrusions by rotating the spindle.

2. Lever pressure measurement

Adjust the position of the counterweight according to the measurement load, put the reference piece into the mandrel and enter the measurement position, start the lever to apply the required load, and after adjusting the reference value of the measuring table, remove the reference piece; The reference end face is positioned, and the axial force of the vertical end face is applied by the lever on the lower end face of the inner ring (that is, the measurement load); the relative height difference between the non-reference end face of the inner ring and the reference end face of the outer ring is measured, and the maximum value of the protrusion is measured by rotating the mandrel and the minimum value.

3. Substitute instrument measurement

Occasionally, manufacturers of assembled angular contact ball bearings do not have measuring instruments. Substitute instruments are often used for measurement. A factory uses a substitute instrument to measure the protrusion when processing a larger series angular contact ball bearing. When using a substitute instrument to measure the bearing protrusion, the substitute instrument can be an improved end pendulum instrument or a height measuring instrument.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano