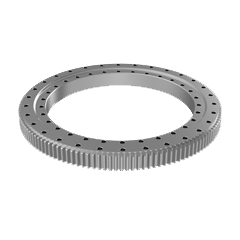

What Causes Rust on Turntable Bearings? Solutions and Rust Prevention Measures

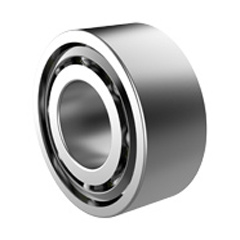

Turntable bearings often rust in the summer high temperature and high humidity season, especially during the hot and humid period of the three dog days, which can easily cause corrosion on the bearing end face near the motor, while the lubricating grease near the outer edge of the inner and outer rings will become yellow-brown and have a special smell of rust, and the other side does not show obvious rust marks. So what causes the rust on turntable bearings? How should we approach and prevent it in daily life?

Causes of rust on turntable bearings

Rust is mainly caused by the reaction of the insulation paint and lubricating grease in the bearings used in the motor equipment due to moisture. When using amino or phenolic insulation paint, the molecular chain of the paint is extremely unstable during the curing process, and low-molecular substances will escape. For example, formaldehyde, when the temperature and humidity are appropriate, formaldehyde reacts with water molecules in the weather to produce formic acid, which will hydrolyze the lubricating grease, and then corrode the bearings to produce rust. Mainly, it is the influence of the climate and environment. In a high temperature and high humidity environment, if the stator drying does not meet the standard, industrial turntable bearings are sealed and packaged during the storage process, and the water vapor will condense in the bearings. This situation mostly occurs in the rainy season in the southern or coastal regions every year.

Solutions to rust on turntable bearings

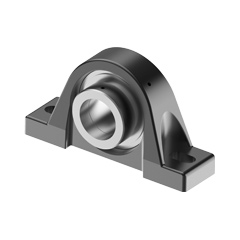

Surface cleaning: Clean the rusted position of the bearing and select the appropriate method. Generally, solvent cleaning method, mechanical cleaning method, and chemical cleaning method are used to clean the surface of the bearing.

Rust prevention treatment: After the surface is cleaned and dried, lubricate and rust-proof the surface of the turntable bearings and spray rust-proof oil for primary rust prevention.

Painting rust-proof paint: Choose rust-proof paint with rust-proof function, immersion paint with welding oxide content and solvent-free paint, and heat them to fully dry and solidify the paint surface.

Prevention measures for rust on turntable bearings

Improve the antirust ability of the bearing: Choose the antirust paint used for the bearing and try to use solvent-free and non-oxidative immersion paint. At the same time, adjust the curing time and temperature, and it is suitable above 130℃ for 180 minutes.

Lubricating grease: Mineral oil-based bearing lubricating grease should be selected, and the environment should be kept clean when adding lubricating grease to avoid water and dust entering the turntable bearings to cause rust or other failures.

Stator drying: The stator drying process is the premise of preventing rust, and ventilation should also be done after drying.

Storage environment: In the storage process, full sealing should be avoided, and good ventilation should be done. The pallet should be placed on the damp warehouse floor, and it should not be placed tightly against the wall.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano