Choose THB's Cam Follower Bearings: The Unrivalled Choice for Cam Mechanical Drive Devices

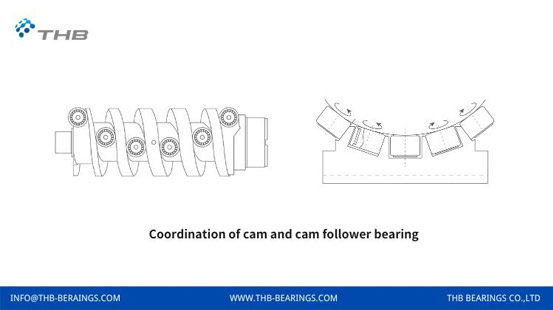

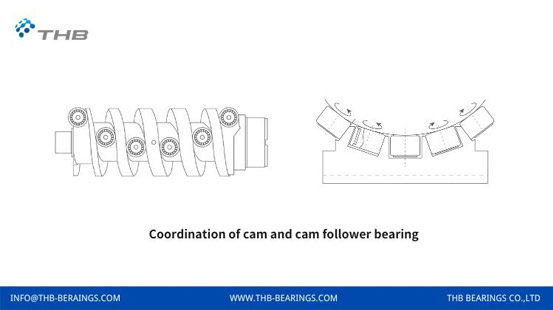

cam mechanical drive device is a kind of basic motion mechanism widely used in various mechanical systems, especially in automation equipment and precision machinery, its application is more extensive. Cam steering mechanism mainly relies on the relative motion between the cam and bearings to realize a variety of complex and precise motion control. In the automated production line, it can be used to realize the positioning of materials, sorting, steering and other actions.

THB provides solutions oriented to customer needs

What makes THB's cam follower bearings the best choice for cam mechanical drive device is THB's deep understanding of the needs of the user's working conditions. Every industry and every application has its own unique requirements, and it is this understanding that allows THB to provide customized solutions for each customer.

THB's team works closely with the customer to gain an in-depth understanding of their challenges and goals in order to design and deliver cam follower bearing thats meets their needs. This customer-oriented solution ensures the efficient operation of cam mechanical drive device in different applications.

THB has professional technical level and product optimization ability

As a leader in the field of cam follower bearings, THB has a wealth of technical knowledge and professional experience. This enables THB to provide high-quality, high-precision bearings for cam mechanical drive device.

THB's technical team continues to explore innovative design and manufacturing techniques to optimize products to meet changing market demands. This level of expertise and product optimization capability provides a solid foundation for the smooth operation of cam mechanical drive device.

1.Positioning

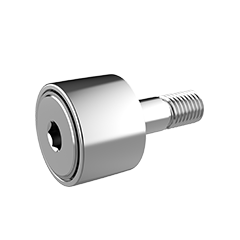

Positioning accuracy/repeated positioning accuracy is one of the core parameter requirements of the cam mechanical drive device.

THB optimizes and provides suitable cam followers according to the parameter requirements of the customer's positioning accuracy and repeating positioning accuracy, combined with the structure of the cam mechanical drive device.

2.Speed & Loading

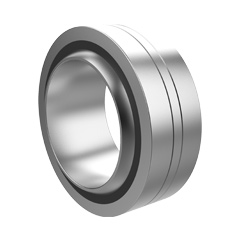

In order to meet the different combination requirements of high/low speed and light/heavy load of the cam mechanical drive device in different application scenarios, THB has carried out special internal optimization on the cam follower bearings, such as the adjustment of the size of the flange side.

3.Serve life

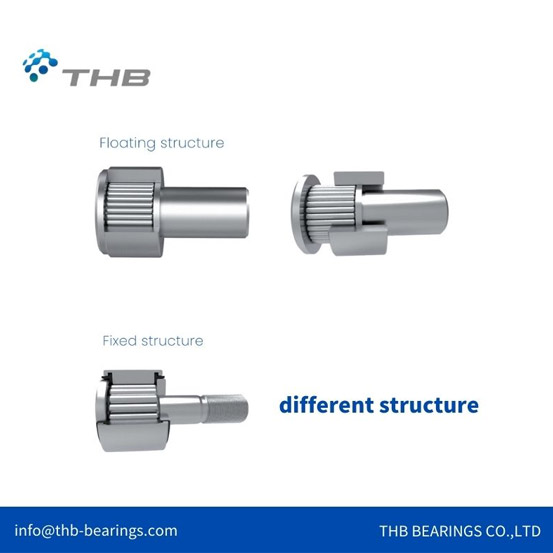

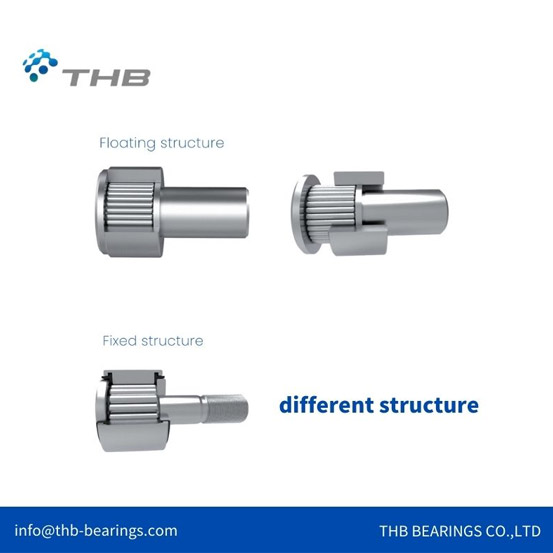

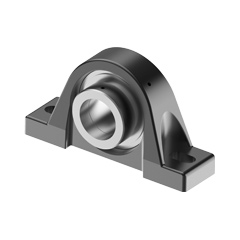

Damage to any part of the automated production line will result in immeasurable losses, and the life of the bearing has an important impact on the stable operation of the production line. It is particularly important to choose a bearing with a fixed structure or a bearing with a floating structure according to different working conditions.

In addition, THB focuses on the application principles behind the equipment products in order to provide better solutions and more suitable products: for example:

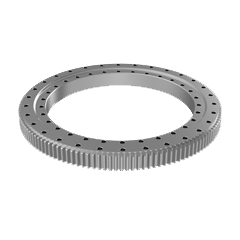

the realization of 0 backlash in the equipment also depends on the overall arrangement of cam follower bearings and the control of the internal parameters of cam follower bearings, as well as on the components that are in direct contact with cam follower bearings, e.g., the CAM wheels.

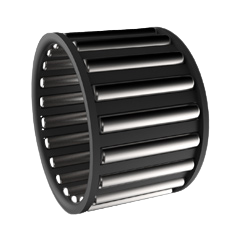

Overall arrangement of roller bearings

All-round supportive maintenance advice

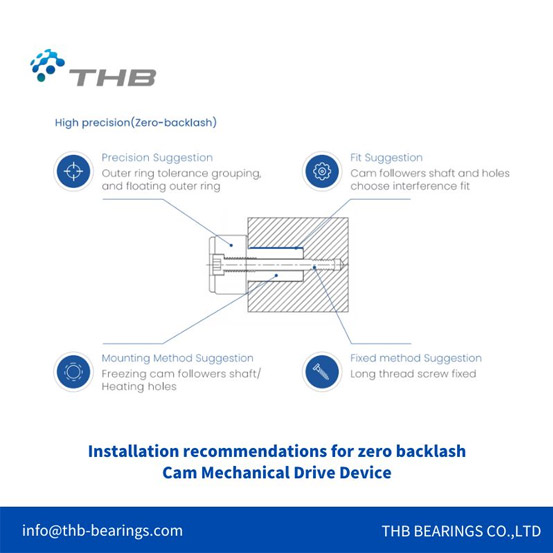

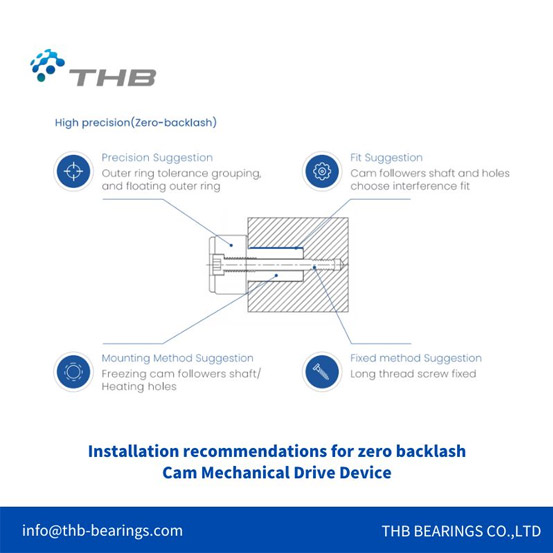

THB understands that it is not enough to have a quality product, but that the customer needs comprehensive support during use. In addition to providing cam follower bearings, THB also offers maintenance advice to users of cam mechanical drive device. This includes installation methods, precautions for use, and maintenance recommendations, etc. THB's goal is to ensure that our customers get the best possible performance and life out of their roller bearings, thus providing them with consistent support for their work.

Example:

Installation recommendations for zero backlash cam mechanical drive device are as follows:

Cam follower bearings size segments for cam machine drive Device

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano