Steadily Handle Eccentric Loads: Three Professional Guidelines on Slewing Rings

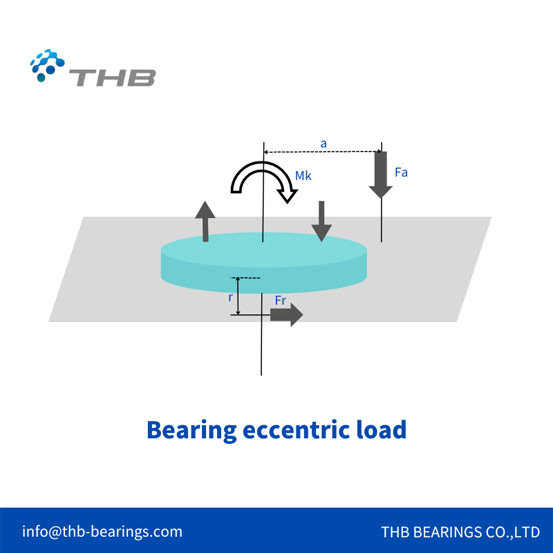

Whether it's the design of skyscrapers, the rotation of wind turbine blades, or the operation of various mechanical equipment, eccentric loads are subtly affecting the stability of our projects. They are like small details in life, small but important. How to choose, use and install turntable bearings under such circumstances has become a common problem faced by our engineers.

Extended Reading:

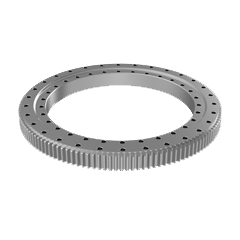

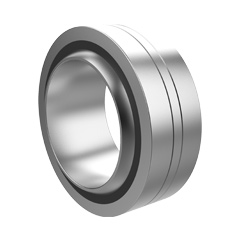

Slewing rings, referred to as slewing bearings or turntable bearings, constitute a distinctive class of bearings meticulously engineered to facilitate the rotational or slewing motion between two components. The slewing bearing application spectrum spans across diverse industries, finding utility in scenarios that demand meticulous control over rotation.

An article to get the full picture of slewingring:Understanding the Essential Role of Slewing Bearings in Modern Machinery.

The key to selection: stability comes first!

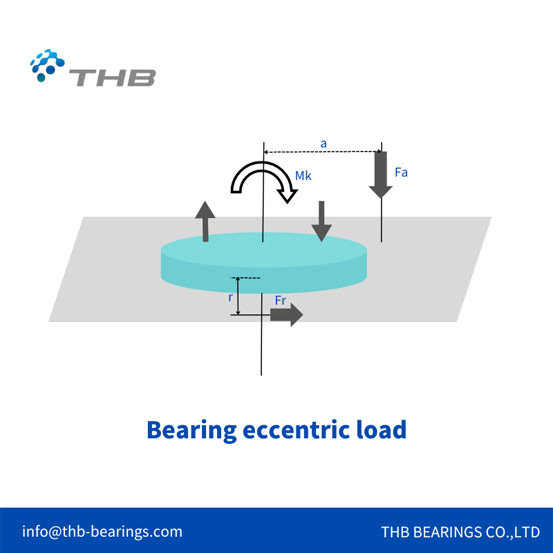

When choosing the right turntable bearing, the primary consideration is its stability. Depending on your engineering needs, make sure that the turntable bearing has sufficient load rating capacity to meet the challenges posed by eccentric loads. Consider the degree of eccentricity possible in your application so that you can select the type and size of turntable bearing that will function properly under such eccentric load conditions.

Points for use: Fully understand the engineering environment!

Once you have selected the right turntable bearing, make sure you fully understand the engineering environment. Different applications may result in different directions and magnitudes of eccentric loads. Design the preload or clearance of the slewing ring bearing appropriately for the different conditions to ensure that the bearing exhibits optimal performance under eccentric loads. In addition, lubrication and sealing are critical to ensure that turntable bearings can continue to operate smoothly in complex environments.

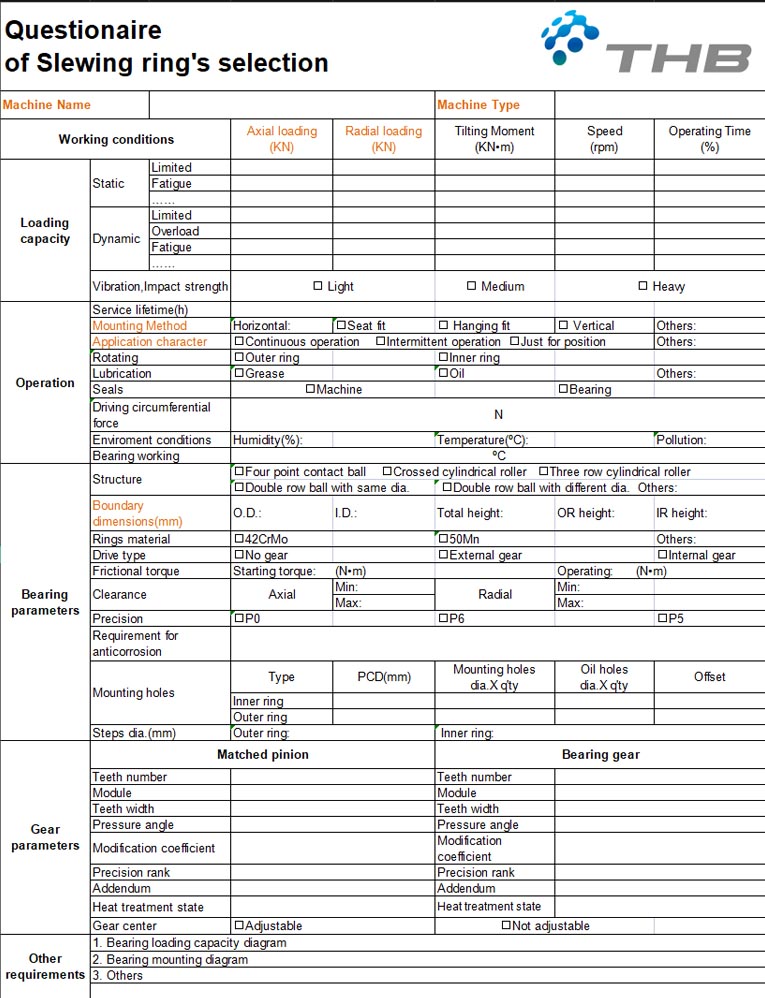

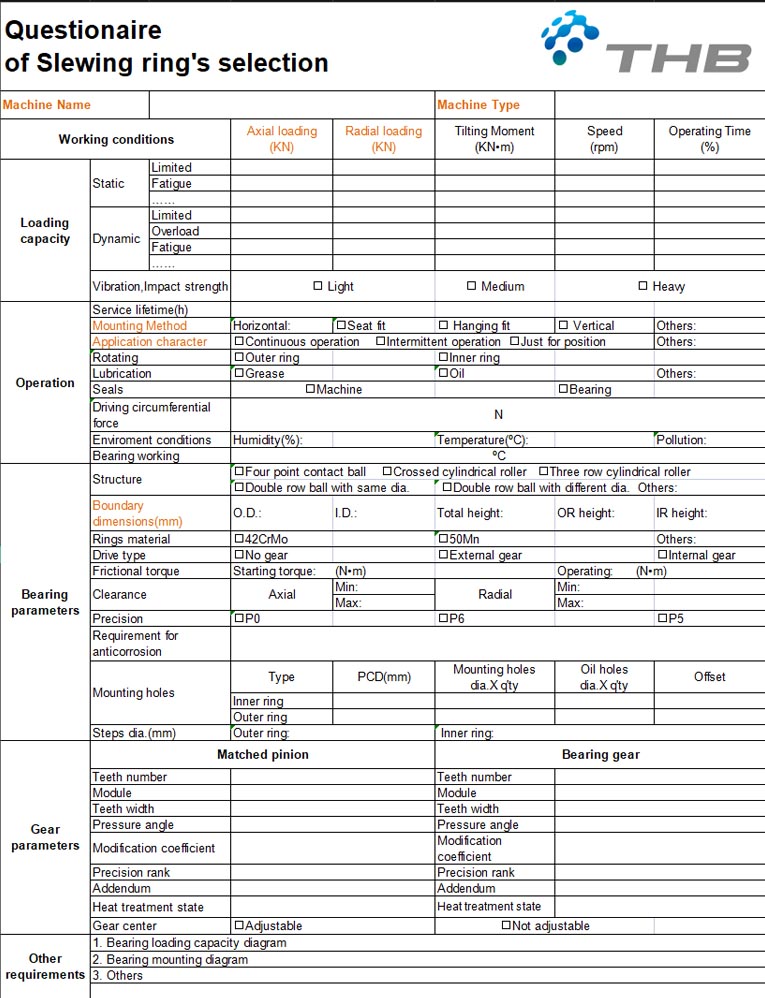

THB provides a condition information collection form to help customers select and validate bearings more accurately.

Installation focus: Precision is king!

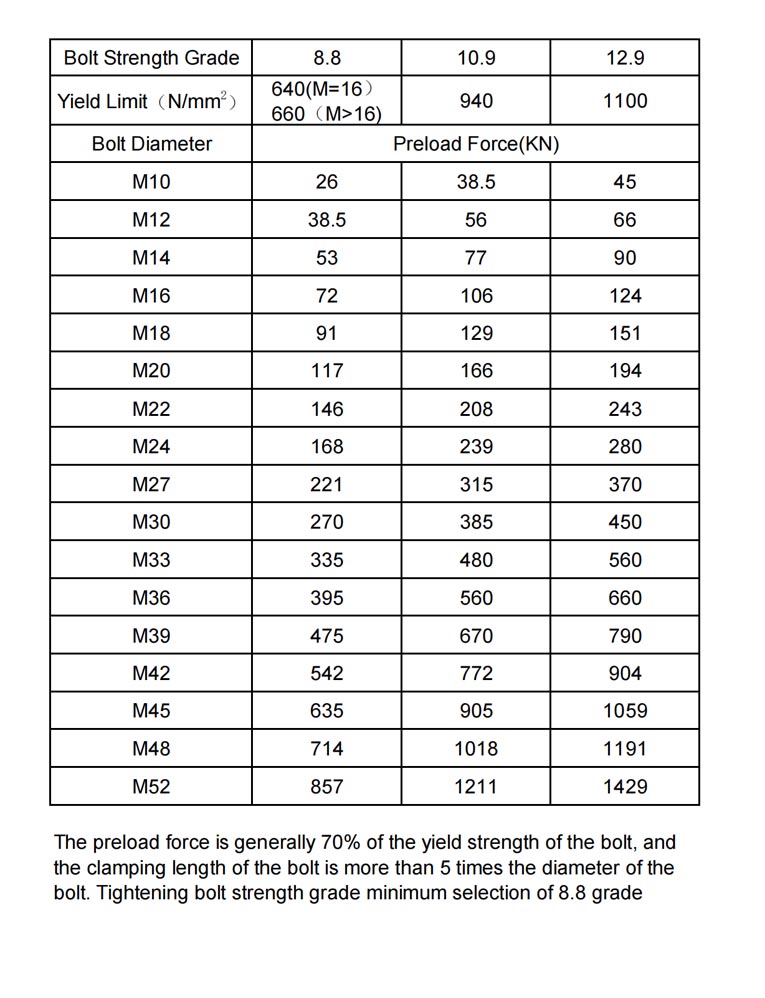

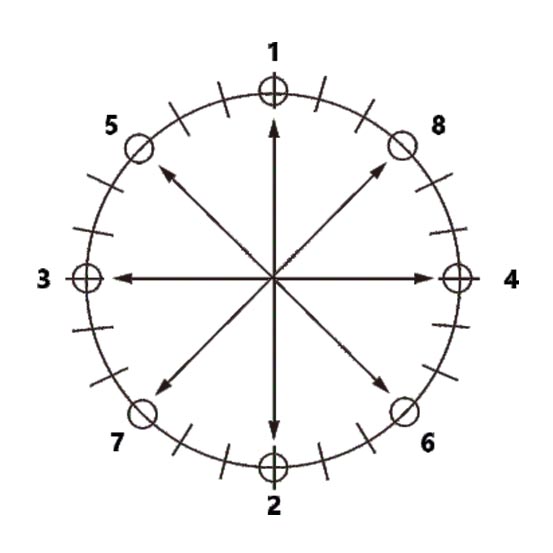

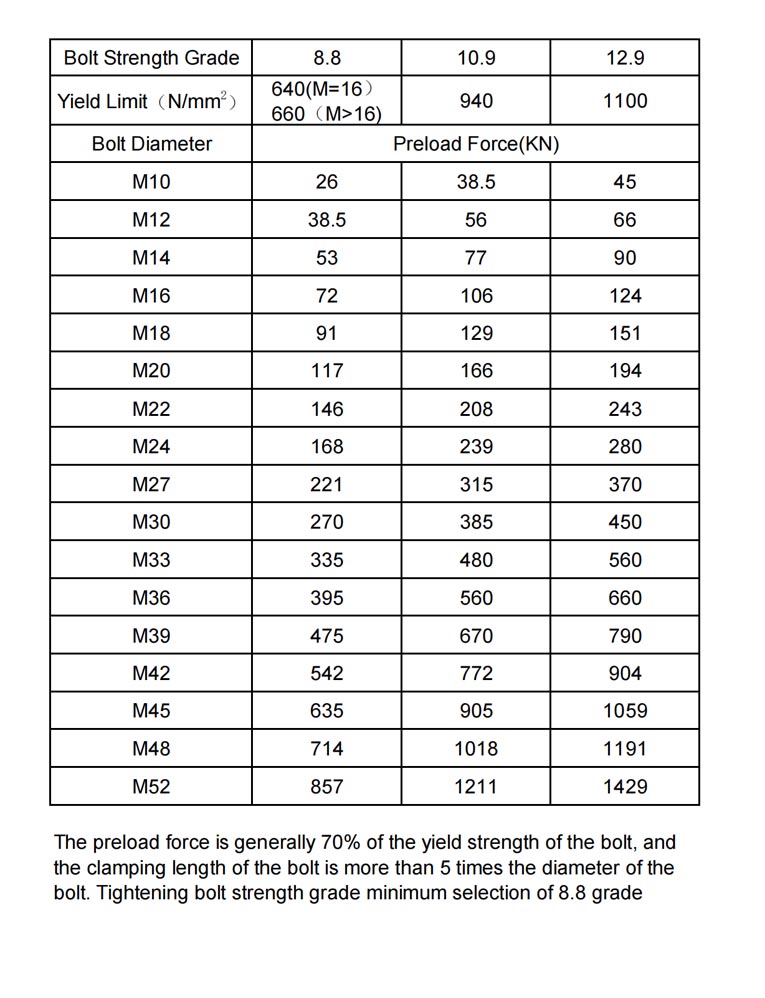

Proper mounting of turntable bearings is critical to their performance and longevity. When mounting, it is important to maintain precise alignment to ensure even distribution of eccentric loads. Also, carefully adjust the preload or clearance to accommodate the expected eccentricity. Ensure that the torque of the fastening bolts or fixing components is in accordance with the manufacturer's recommendations to avoid unwanted stress concentrations.

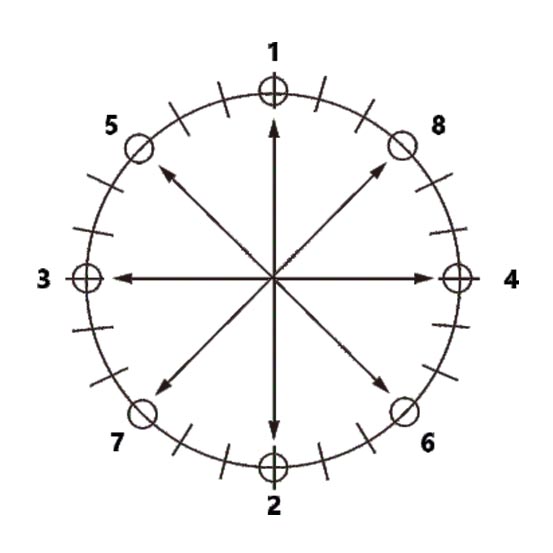

Diagram of bolt tightening sequence

Whether it's wind turbine blades, construction equipment, or engineering machinery, the correct selection, use, and installation of slewing bearings under eccentric loads will directly affect the performance and reliability of your equipment. Be sure to define the key requirements for slewing bearings, such as rated load, lubrication, preloading, etc., to ensure you make wise decisions in technical decisions.

Whether it's resisting unpredictable loads or ensuring the long-term stable operation of the equipment, slewing bearings provide you with solid support. Let's fully understand and take advantage of the benefits of slewing bearings together, and jointly face the challenges of eccentric loads.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano