Market and Technology of Industrial Robot Bearings

Industrial robots are multifunctional and multi-degree-of-freedom mechanical devices that can repeat programmed operations or movements under automatic control. They are important engineering automation equipment in modern manufacturing industry. Industrial robots are complex operation systems that include several parts such as control system, driving system, mechanical system, perception system, etc.

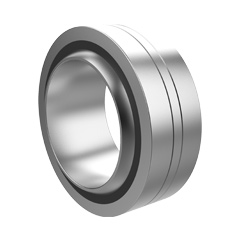

Technical aspects of robot bearings

Design technology

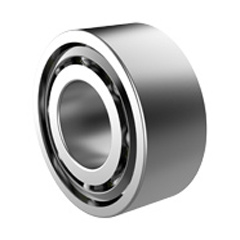

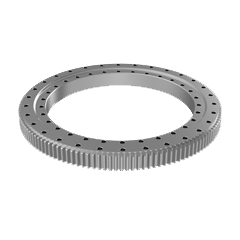

In order to ensure sufficient load capacity, precise positioning and flexible operation of thin-walled robot bearings, the bearing design analysis and the determination of the main parameters cannot simply be focused on the rated dynamic load, but must be optimized for multiple objectives, including the rated dynamic load, stiffness and friction torque. Finite element analysis methods based on ring and rack deformation must be used for the design of thin-walled bearings.

Manufacturing technology

High-precision detection technology of robot bearing dynamic mass;

Heat treatment process of thin-walled bearing ring microdeformation;

Grinding process of bearing ring precision control based on grinding deformation layer;

Precise control technology of negative clearance of thin-walled bearings;

Precise control technology of thin-walled angular contact ball bearings protrusion;

Precision assembly technology of thin-walled bearings;

Non-contact measurement technology of thin-walled bearing rings.

Technical route for the development of robot bearings

We need to make full use of the basic role of market allocation of resources to promote the development of industrial robot bearing industry. We should not only tackle key technical problems of robot bearings, gradually replace imports, but also avoid overcapacity of high-end products like industrial robot bearings. We should adopt the parallel development route of research and development, engineering, and industrialization, rather than the conventional model of doing one thing at a time. Industry-leading companies, research institutions, and universities should summarize, integrate, and deepen fragmented research achievements in industrial robots over the years, especially in testing, inspection, and industrial trials to achieve engineeringization. Meanwhile, we should meet the needs of the market by implementing technical renovation projects, establishing production capacity, and serving the main engine industry. We should advocate complementary advantages and win-win cooperation between large enterprises with research and development capability and foundation on industrial robot bearings and small and medium-sized enterprises with small-batch production experience in industrial robot bearings.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano