Navigating The Waves: Custom Cam Rollers In Marine Equipment Design

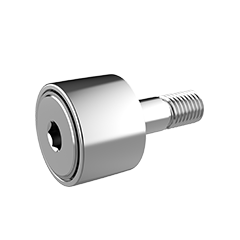

When it comes to marine equipment design, ensuring smooth and efficient operations while withstanding harsh environmental conditions is crucial. Custom cam rollers play a vital role in achieving this objective. These specially designed components offer unparalleled performance and versatility, making them an essential element in marine equipment applications.

At THB BEARINGS, our commitment to excellence and innovation drives us to develop superior-quality custom cam rollers that exceed the expectations of our customers. In this blog post, we will explore the significance of custom cam rollers in marine equipment design, highlighting their benefits and diverse applications.

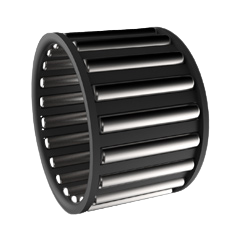

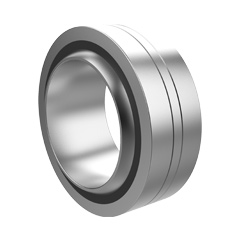

Understanding Custom Cam Rollers

Custom cam rollers are precision-engineered components that facilitate smooth linear or rotational movement in various industrial applications. They are particularly valued in marine equipment design due to their exceptional load-bearing capacity and ability to withstand extreme conditions such as high humidity, saltwater exposure, and temperature variations.

Benefits of Custom Cam Rollers in Marine Equipment Design

Durability

Marine applications demand components that can withstand the harsh operating conditions. Custom cam rollers are constructed using high-strength materials such as stainless steel or corrosion-resistant alloys, ensuring long-lasting performance even in saltwater environments.

Versatility

Custom cam rollers are available in various sizes, designs, and configurations to meet the specific requirements of marine equipment. Whether it's guiding marine cables, operating hatches, or facilitating deck movements, these rollers can be customized accordingly.

Improved Performance

With their smooth rolling action and low friction coefficient, custom cam rollers minimize wear and tear, resulting in enhanced equipment reliability and longevity. Their precise movement also contributes to increased operational efficiency, reducing downtime and maintenance costs.

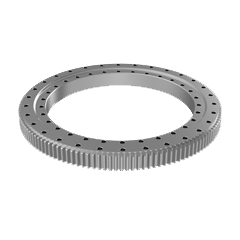

Applications of Custom Cam Rollers in Marine Equipment

Winch Systems: Custom cam rollers are crucial in winch systems to ensure smooth winding or unwinding of cables, ropes, or chains. Their robust construction and high load-bearing capacity allow for effective operation, even under heavy loads.

Seating Mechanisms: Marine equipment often includes seating mechanisms that require precision movement. Custom cam rollers provide the necessary stability and controlled motion for seat adjustments, ensuring passenger comfort and safety.

Sliding Doors and Hatches: From mega yachts to sailboats, custom cam rollers are extensively used in sliding doors and hatches. These rollers enable effortless opening and closing while maintaining watertight integrity during turbulent conditions.

Deck Equipment: In marine applications, custom cam rollers support various deck equipment, such as cranes and davits, ensuring efficient load handling and movement. Their ability to withstand corrosion and extreme loads makes them indispensable for such operations.

Partnering with THB BEARINGS for Custom Cam Rollers

At THB BEARINGS, we pride ourselves on delivering top-notch custom cam rollers that cater to the unique needs of the marine industry. With our state-of-the-art manufacturing facilities and engineering expertise, we can develop rollers that offer unparalleled performance, durability, and reliability.

In conclusion, custom cam rollers play a significant role in marine equipment design, enhancing performance, durability, and operational efficiency. Their diverse applications across winch systems, seating mechanisms, sliding doors and hatches, and deck equipment make them indispensable components. By partnering with THB BEARINGS, marine equipment manufacturers can benefit from our expertise to optimize their designs and deliver exceptional products that withstand the challenges of marine environments.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano