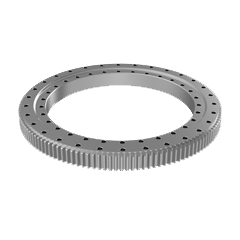

Crossed Roller Bearings Are Important Components of Industrial Robots

Industrial robots usually operate in complex environments, closely interact with human staff, and perform a variety of tasks. The cross roller bearing is an important key component of industrial robots, and its performance is related to the overall competitiveness of the industrial robot industry. Therefore, in response to the continuous development of social demand for industrial robots, it is urgently necessary to carry out research and development of matching bearings for industrial robots and key information technology innovation for industrialization, to ensure the improvement of various performance analysis indicators of cross roller bearings, and to improve the market competitiveness of industrial robots and promote the rapid development of the artificial intelligence equipment industry.

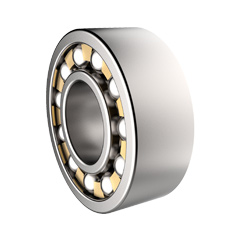

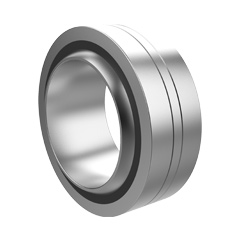

Cross roller bearing products can withstand loads in all directions, such as radial loads, axial loads, and moment loads, and have high rigidity. Therefore, they are suitable for joint or rotating parts of industrial robots, rotating worktables of machining centers, rotating parts of robots, precision rotating worktables, measuring instruments, IC manufacturing equipment, and other purposes.

Cross roller bearings have high rotational accuracy

Because there is a spacer between the vertical columns of rollers, the side collapse of rollers or the friction between rollers is prevented, so the increase of rotational torque can be prevented. In addition, the one-sided contact or locking phenomenon of rollers will not occur. Even if a preload is applied, stable rotational motion can be obtained. Moreover, since the inner or outer ring of the cross roller bearing is constructed in two parts, the preload can be adjusted, so high-precision rotational motion can be obtained.

Cross roller bearings are easy to operate

The split inner or outer ring of the cross roller bearing is fixed together with the cross roller axial ring after the rollers and spacers are loaded, to prevent separation from each other. Therefore, the operation of installing the cross roller bearing is very simple.

Cross roller bearings prevent roller side collapse

The mutual friction between rollers is eliminated by the spacer, and the side collapse of rollers is also prevented, so stable rotational torque can be obtained.

Cross roller bearings greatly improve rigidity

Unlike the use of double row thin angular contact ball bearings, because the rollers are arranged vertically and crosswise, only one cross roller bearing is needed to bear loads in all directions, and the rigidity is increased by more than three times.

Cross roller bearing products, as important components of industrial robots, enable them to have good operational flexibility and functionality. They also enable industrial robots to be suitable for multi-variety and small-batch production, to respond quickly to changes in market and consumer demand. Furthermore, for industrial robots used for large loads, wide motion ranges, and high movement speeds, cross roller bearings are still important key components.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano