The Role of Yoke Type Track Rollers in Automated Warehousing

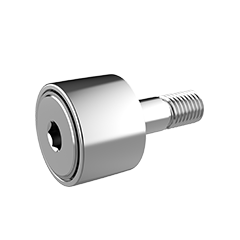

In the world of smart warehousing, efficiency and accuracy are key factors in ensuring smooth operations. One important component that plays a crucial role in the functioning of automated systems is yoke type track rollers. These rollers are essential in guiding and supporting conveyor systems, allowing for the smooth movement of goods throughout the warehouse. In this blog, we will explore the role of yoke type track rollers in smart warehousing and how they contribute to the overall efficiency of the operation.

What are yoke type track rollers?

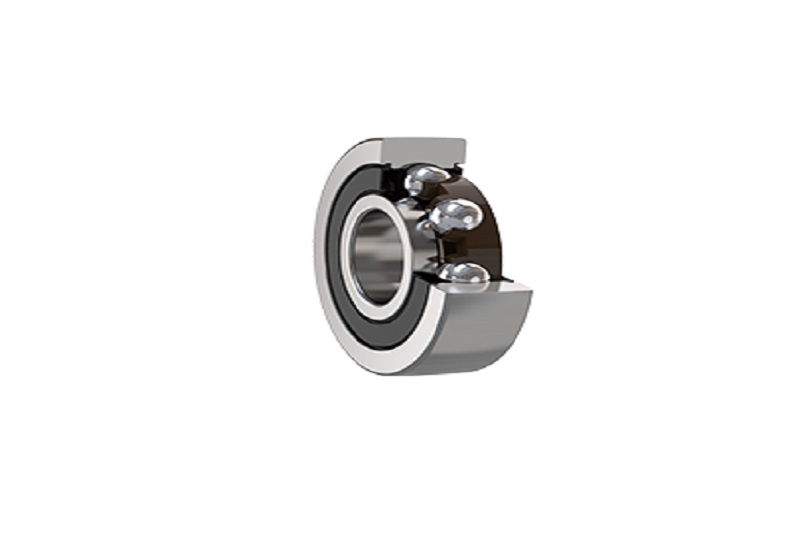

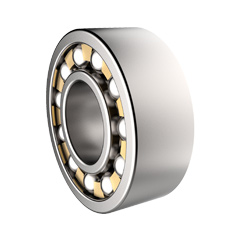

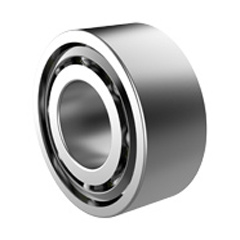

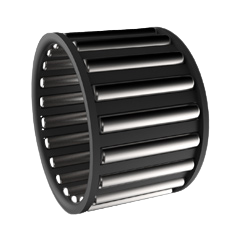

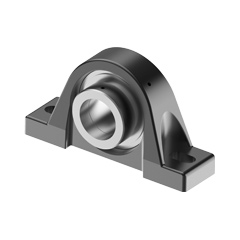

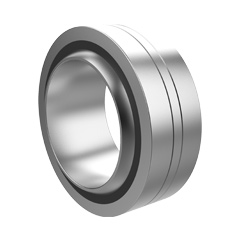

Yoke type track rollers are a type of bearing that is used in various applications, including conveyor systems. These rollers are designed to withstand heavy loads and provide smooth movement along the track. Yoke type track rollers consist of an outer ring, inner ring, needle rollers, and a cage assembly. The outer ring is designed to guide the roller along the track, while the inner ring supports the load. The needle rollers facilitate smooth movement and reduce friction, while the cage assembly keeps the rollers aligned. Overall, yoke type track rollers are essential components in conveyor systems, ensuring the efficient movement of goods within the warehouse.

The role of yoke type track rollers in automated warehousing

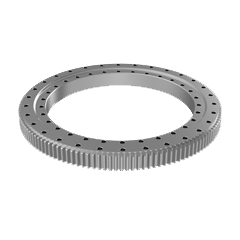

In smart warehousing, automation plays a crucial role in increasing efficiency and reducing errors. Yoke type track rollers are essential components in automated conveyor systems, guiding and supporting the movement of goods throughout the warehouse. These rollers are designed to withstand heavy loads and provide smooth movement along the track, ensuring that goods are transported quickly and efficiently. By using yoke type track rollers in conveyor systems, warehouses can increase productivity, reduce labor costs, and improve overall efficiency.

Benefits of using yoke type track rollers in automated warehousing

There are several benefits to using yoke type track rollers in smart warehousing. One of the main advantages is their ability to withstand heavy loads and provide smooth movement along the track. This ensures that goods are transported quickly and efficiently, reducing the risk of errors and delays. Yoke type track rollers also help to reduce friction, prolonging the life of the conveyor system and reducing maintenance costs. Additionally, these rollers are highly durable and can withstand harsh operating conditions, making them ideal for use in warehouses with high throughput. Overall, yoke type track rollers play a crucial role in the efficiency and effectiveness of smart warehousing operations.

In conclusion, yoke type track rollers are essential components in smart warehousing, playing a crucial role in guiding and supporting conveyor systems. These rollers are designed to withstand heavy loads and provide smooth movement along the track, ensuring that goods are transported quickly and efficiently. By using yoke type track rollers in automated conveyor systems, warehouses can increase productivity, reduce labor costs, and improve overall efficiency. With their ability to withstand harsh operating conditions and reduce maintenance costs, yoke type track rollers are an essential component in the success of smart warehousing operations.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano