Ultra-Small Cross Roller Bearings Help Shrink Automated Equipment Designs

When it comes to designing automated equipment with limited space, finding a bearing that offers both precision and compactness can be a challenge. Typically, complex or high-speed rotating loads require large bearings with solid construction to ensure accuracy and rigidity. However, the development of crossed roller bearings has revolutionized the way we approach space-constrained machine designs. In this article, we explore the benefits of ultra-small cross roller bearings and how they can help shrink automated equipment designs without compromising on precision.

The Power of Cross Roller Bearings

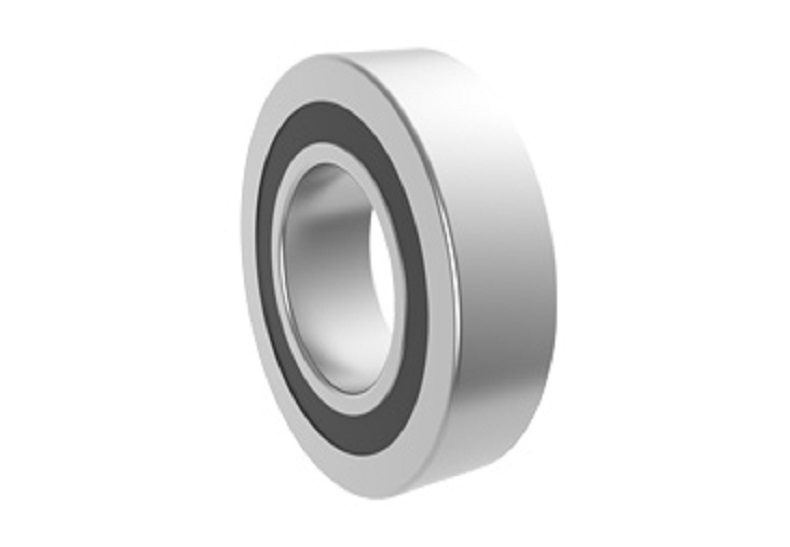

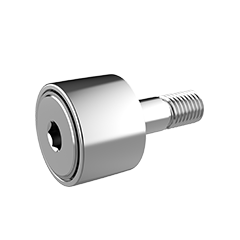

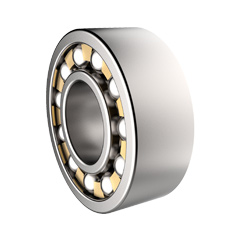

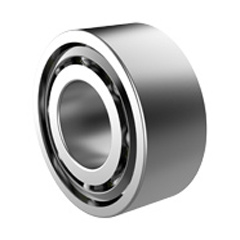

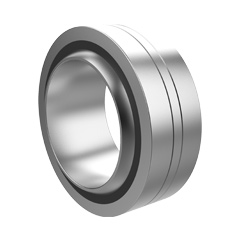

Crossed roller bearings are advanced products designed specifically for space-constrained automated machine designs. These bearings are engineered with precision in mind, offering exceptional accuracy and rigidity despite their compact size. By incorporating rollers that cross at right angles between inner and outer rings, crossed roller bearings achieve increased roller contact with the raceways, enabling them to withstand radial, thrust, and moment loads with minimal deflection. This unique construction allows for precise, repeatable motion, making them an excellent choice for applications that require high precision and compactness.

Cross Roller Bearings Help Shrinking Automated Equipment Designs

Maximizing Space Efficiency

One of the significant advantages of ultra-small crossed roller bearings is their ability to maximize space efficiency. In space-constrained machine designs, every millimeter counts. By opting for crossed roller bearings, engineers can take full advantage of the compactness of these bearings, allowing for more efficient use of available space. This is particularly beneficial in applications where multiple components need to be integrated within a limited area. With ultra-small crossed roller bearings, designers can optimize the layout of their automated equipment without compromising on performance.

Precision in Small Packages

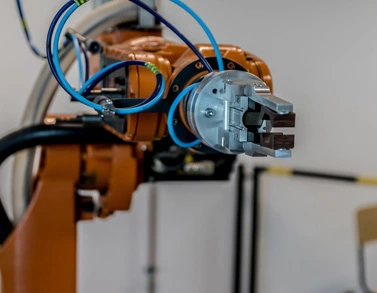

Despite their small size, ultra-small crossed roller bearings deliver impressive levels of precision. The crossed roller configuration ensures minimal rolling friction and allows for smooth and accurate motion control. Whether it's robotic arms, automated assembly lines, or precision measurement devices, these bearings provide the necessary precision to achieve consistent and reliable performance. The ability to maintain accuracy in compact designs opens up new possibilities for miniaturized automation, where space limitations were once a hindrance.

Enhanced Performance

By incorporating ultra-small crossed roller bearings into automated equipment designs, engineers can enhance overall system performance. These bearings offer improved load-carrying capabilities, enabling machines to handle demanding tasks with ease. The enhanced rigidity and load capacity of crossed roller bearings contribute to smoother operation, reduced vibration, and increased durability. This translates to higher productivity, reduced downtime, and improved product quality. Whether it's in industrial automation, medical devices, or semiconductor manufacturing, ultra-small crossed roller bearings are helping to push the boundaries of automated equipment performance.

In the world of automated equipment design, precision and compactness are essential. With the introduction of ultra-small crossed roller bearings, engineers can now achieve both. These advanced bearings provide the necessary accuracy and rigidity within the tight confines of space-constrained designs, revolutionizing the way we approach automation. By maximizing space efficiency, offering precision in small packages, and enhancing overall performance, ultra-small crossed roller bearings have become a vital component in shrinking automated equipment designs. When it comes to precision and compactness, these bearings prove that bigger is not always better. Embrace the power of ultra-small crossed roller bearings and unlock new possibilities in automated equipment design.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano