The Imperative of Self-Aligning Linear Ball Bearings in AGV Applications

Navigating the World of AGVs

Automated Guided Vehicles (AGVs) have become indispensable in modern industrial settings, streamlining material handling and logistics operations. At the heart of these automated systems lies a critical component – the self-aligning linear ball bearing. In this blog, we delve into the indispensable requirement of self-aligning linear ball bearings in AGV applications, exploring how these bearings contribute to the efficiency and reliability of AGV systems.

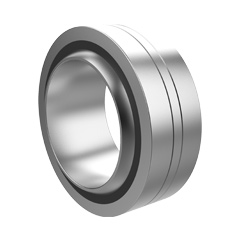

Understanding Self-Aligning Linear Ball Bearings

Before we explore their role in AGVs, it's essential to comprehend the design and functionality of self-aligning linear ball bearings. Unlike traditional linear bearings, self-aligning variants are engineered to accommodate misalignment between the shaft and the housing, ensuring smooth operation even in less-than-ideal conditions. This adaptability is crucial in dynamic environments where precise alignment may be challenging to maintain.

Precision and Adaptability in AGV Movements

AGVs operate in dynamic environments, navigating through warehouses, manufacturing floors, and distribution centers. The ability to adapt to changing conditions is paramount for the smooth functioning of these vehicles. Self-aligning linear ball bearings excel in providing the necessary precision and adaptability required for AGV movements.

These bearings facilitate smooth linear motion while accommodating any misalignment that may occur due to factors like uneven surfaces or minor deviations in the AGV's path. This adaptability ensures consistent and reliable performance, minimizing wear and tear on the bearings and enhancing the overall longevity of AGV systems.

Enhancing Reliability and Efficiency

Reliability is a non-negotiable factor in AGV operations, where any downtime can disrupt the entire logistics chain. Self-aligning linear ball bearings play a pivotal role in enhancing the reliability of AGV systems by mitigating the impact of misalignments. Their ability to absorb and adjust to deviations in the trajectory of the AGV contributes to uninterrupted and efficient material handling processes.

Moreover, these bearings contribute to the overall efficiency of AGVs by reducing friction and ensuring smooth linear motion. The result is improved energy efficiency, reduced maintenance requirements, and optimized performance – factors that are crucial for the sustained success of AGV applications.

Future-Proofing AGV Technology

As AGV technology continues to evolve, the demand for robust and adaptable components becomes increasingly pronounced. Self-aligning linear ball bearings not only meet the current requirements of AGV applications but also future-proof these systems. Their capacity to handle misalignments, combined with advancements in material technology, positions them as essential components for the next generation of agile and efficient AGV solutions.

In the dynamic landscape of automated material handling, AGVs stand as technological marvels, and at their core lies the reliability and adaptability of self-aligning linear ball bearings. These bearings play a pivotal role in ensuring precise and efficient linear motion, even in challenging environments. As industries embrace the efficiency of AGV systems, the indispensable requirement for self-aligning linear ball bearings underscores their crucial role in propelling the future of automated logistics and material handling.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano