Importance of Proper Lubrication in Maximizing the Performance of Radial Spherical Plain Bearings

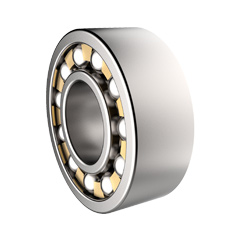

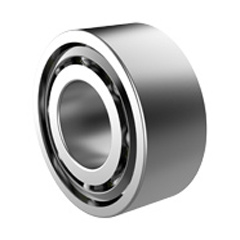

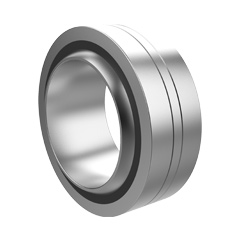

Radial spherical plain bearings play a crucial role in various machinery and equipment by allowing for rotation and movement in multiple directions. These bearings are designed to accommodate heavy loads and shock loads, making them essential components in industries like agriculture, automotive, and construction. However, in order for radial spherical plain bearings to perform at their best, proper lubrication is key.

Effects of Improper Lubrication on Radial Spherical Plain Bearings

One of the most common causes of premature failure in radial spherical plain bearings is inadequate or improper lubrication. Without proper lubrication, friction between the bearing surfaces can lead to excessive wear and damage. This can result in reduced performance, increased energy consumption, and ultimately, costly repairs or replacements.

Choosing the Right Lubrication for Radial Spherical Plain Bearings

When it comes to lubricating radial spherical plain bearings, there are several factors to consider. The type of lubricant, the operating conditions, and the load requirements all play a role in determining the most suitable lubrication. Some common types of lubricants used for radial spherical plain bearings include grease, oil, and solid lubricants.

Grease is a popular choice for its ease of application and ability to provide good lubrication under normal operating conditions. Oil, on the other hand, is preferred for high-speed applications or environments with high temperatures. Solid lubricants, such as graphite or PTFE, are often used in applications where continuous lubrication is required or where re-lubrication is difficult.

Regular Maintenance for Longevity of Radial Spherical Plain Bearings

In addition to selecting the right lubrication, regular maintenance is essential for maximizing the performance and longevity of radial spherical plain bearings. This includes monitoring the condition of the bearings, re-lubricating as needed, and replacing worn or damaged components. By following a proactive maintenance schedule, equipment owners can prevent breakdowns, extend the life of their bearings, and avoid costly downtime.

In conclusion, proper lubrication is essential for maximizing the performance of radial spherical plain bearings. By choosing the right lubrication, following a regular maintenance schedule, and monitoring the condition of the bearings, equipment owners can ensure that their machinery operates smoothly and efficiently. Investing in high-quality lubricants and implementing effective maintenance practices can help extend the life of radial spherical plain bearings and save money in the long run. So remember, when it comes to radial spherical plain bearings, proper lubrication is key.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano