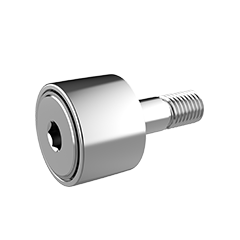

How to Test the Quality of Stud Type Track Rollers?

During the operation of stud type track rollers, although the national standard judges whether the vibration exceeds the standard by vibration speed, in practice, special attention should be paid to the change of acceleration value of stud type track rollers. The damage process of stud type track rollers mostly shows fatigue damage in the early stage, which is generally manifested as a significant increase in acceleration. With the development of fatigue, the vibration speed and displacement gradually increase, indicating that the stud type track rollers have fatigue failure. Especially when detecting stud type track rollers, attention should be paid to whether the vibration value has unstable swing. If swing occurs, it indicates the presence of unstable vibration signals, and the acceleration is also large. Especially when the speed simultaneously increases, there is a high possibility of "loose sleeve" fault of stud type track rollers.

Vibration standards for stud type track rollers quality inspection

Vibration acceleration national standard (commonly known as Z standard)

This standard was formulated relatively early. It judges the quality level of stud type track rollers by measuring the vibration acceleration value when they rotate. It is divided into three quality levels, Z1, Z2, and Z3, from low to high. At present, stud type track roller manufacturers still use vibration acceleration value to measure the quality of stud type track rollers, which simply reflects the fatigue life of stud type track rollers.

Vibration velocity standard (commonly known as V standard)

As the original vibration acceleration standard has not yet been abolished, this standard appeared after the standard was issued by the Ministry of Machinery Industry, combined with actual conditions and needs, referencing European standards. It divides the quality level of stud type track rollers by detecting the vibration velocity in different frequency bands. It is divided into five quality levels, V, V1, V2, V3, and V4. The quality levels of various ball stud type track rollers are V, V1, V2, V3, and V4 from low to high, while the quality levels of various roller stud type track rollers are V, V1, V2, and V3 from low to high. It reflects the quality of stud type track rollers by detecting the vibration velocity in different frequency bands. It can roughly analyze whether there are geometric size problems, quality problems of raceway/rolling elements, and quality problems of retainer in stud type track rollers, which has made significant progress compared to measuring the quality of stud type track rollers with vibration acceleration. Currently, stud type track rollers exported to Europe, military and aerospace industries are inspected according to this standard, and detecting the quality of imported stud type track rollers and distinguishing counterfeit imported stud type track rollers provide feasible solutions.

There are currently two parallel standards for stud type track roller quality inspection, and stud type track rollers with high Z standard quality may not necessarily perform well in V standard detection. There is no correspondence between the two, which requires special attention in stud type track roller quality inspection.

Detecting stud type track rollers in use with vibration measurement instrument

By detecting the vibration velocity in different frequency bands of stud type track rollers to reflect the quality of stud type track rollers. It can roughly analyze whether there are geometric size problems, quality problems of raceway/rolling elements, and quality problems of retainer in stud type track rollers, which has made significant progress compared to measuring the quality of stud type track rollers with vibration acceleration. At present, stud type track rollers exported to Europe, military and aerospace industries are inspected according to this standard, and detecting the quality of imported stud type track rollers and distinguishing counterfeit imported stud type track rollers provide feasible solutions.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano