Cam Roller

GET A QUOTE

ANY QUESTIONS

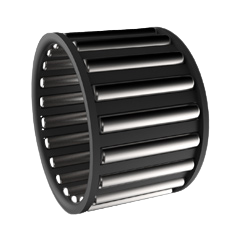

Cam roller, also called ball bearing track roller. They are non-separable,single-row or double-row ball bearings with thick outer rings.

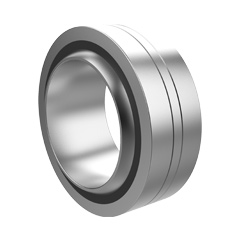

In addition to withstanding very high radial loads, these bearings can also withstand axial forces in both directions.

Cam roller can support slight misalignment and inclined operation caused by high radial load and axial load, and have certain advantages in high-speed performance.

Series And Varients Of THB Cam Rollers

Types of THB Ball Bearing Track Rollers

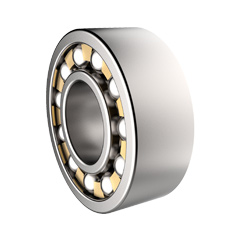

The cam rollers provided by THB have two types, single-row ball bearing track rollers and double-row ball bearing track rollers.

Single-row products include the following models: LR6, LR60, LR2;

Double-row products include the following models: LR50, LR52, LR53.

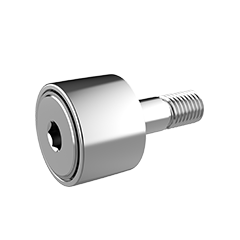

There are several types of cam rollers: cam roller with inner ring, cam roller with support bolts, and cam roller with plastic cover on the outer ring. The cam roller constructions include outer ring, inner ring ball and nylon cage assemblies with crowned or cylindrical outer surfaces.

Size Range of THB Ball Bearing Track Rollers

The size range of single row ball bearing rollers is: inner diameter 4-45mm, outer diameter 13-90mm, width 4-19mm

The size range of double row ball bearing rollers is: inner diameter 5-40mm, outer diameter 17-100mm, width 7-36.5mm

For more sizes and constractions of ball bearing rollers, please contact THB!

Single row deep groove ball bearing yoke type track rollers.

|

Dimensions |

Basic load rating |

Technical Information of THB Cam Rollers

Sealing

Ball bearing track rollers are sealed on both sides.

Sealing Description

| 2RS | Lip seal on both sides of the yoke type track roller. |

| 2Z | Metal shield on both sides of the track roller bearing. |

| 2RSR | Radical contact lip seal on both sides of the yoke type track roller bearing. |

| 2ZL | Sealing shield with lamellar rings on both sides of the track roller bearing. |

Lubrication

THB Ball bearing track rollers are filled with lithium-based grease at factory. In some cases, double-row ball rollers can also be re-lubricated through lubricating holes in the inner bore surface.

THB can also provide targeted lubrication programs, if necessary, please contact the THB technical department.

Working temperature

Due to restrictions on the grease, retainer materials and seal materials, ball bearing

track rollers are suitable for the working temperature of -20°C to +120°C

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano