When it comes to industrial machinery and mechanisms that involve heavy loads and rotational or linear movements, choosing the right support system is crucial. One key component that often comes under consideration is support roller bearings. These are specially designed bearings that can handle both radial and axial loads, offering efficacy and reliability for a vast array of applications. Today, we're placing the spotlight on THB Bearings, a brand known for its exceptional quality and performance in this domain.

Understanding Support Roller Bearings

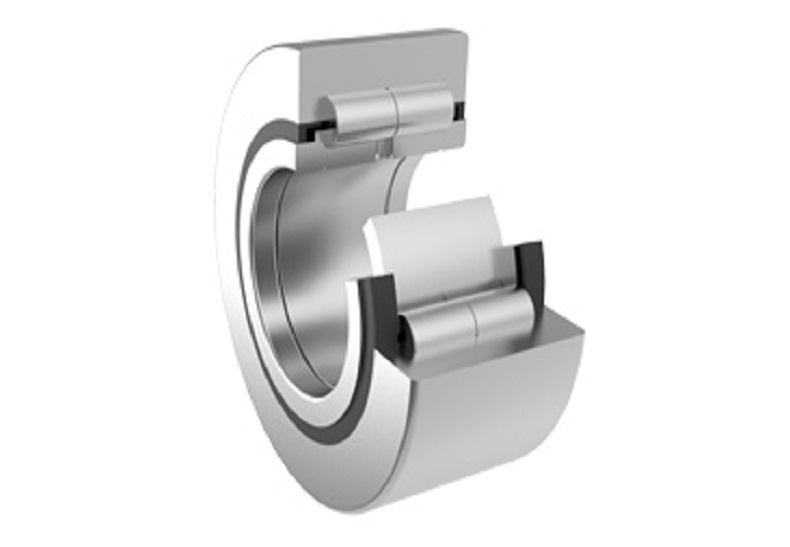

Before we dive into the specifics of selecting the right kind of support roller bearings, let's understand what these components are and why they're essential. Support roller bearings are a type of rolling-element bearing that includes a thick-walled outer ring, which enables them to accommodate heavy radial and axial loads in both directions. They are typically used in machinery where precision and durability are paramount, such as in the metal, textile, printing, and conveyor sectors.

The anatomy of these bearings is designed to provide stability and support, minimizing the friction that occurs as a mechanism operates. This not only enhances performance but also extends the lifespan of both the bearing and the machinery it supports. THB Bearings, in particular, stands out in the market for their high-quality materials and engineering that ensure optimal performance under varied conditions.

Selecting the Right Bearing for Your Needs

When considering support roller bearings for your operations, several factors come into play. Here's how you can make sure you're choosing the right bearings for your needs:

Load Capacities and Speed Requirements

Determine the radial and axial load capacities required by your application. THB Bearings offers a wide range of support roller bearings designed to accommodate light to heavy load capacities. Similarly, consider the speed at which your machinery operates. Higher speed applications may require bearings with specific design features, such as enhanced lubrication capabilities.

Environmental Conditions

The operating environment plays a critical role in selecting the right bearing. Conditions such as high temperatures, corrosive substances, or the presence of water and dust can significantly affect bearing performance. THB Bearings provides solutions with various sealing and material options to withstand harsh environments, ensuring reliability and a longer service life.

Maintenance and Accessibility

Consider how often maintenance can be performed on the bearings and how easily they can be accessed for such tasks. Some applications might benefit from THB’s bearings that feature designs aimed at reducing maintenance needs or simplifying the maintenance process.

Customization and Technical Support

There might be instances where standard bearings don’t quite meet the specific requirements of your application. THB Bearings stands ready to work with their clients, providing custom solutions and technical support to ensure the perfect fit for any specialized needs.

The THB Advantage

Choosing support roller bearings from THB Bearings comes with significant advantages. Not only does THB invest in research and development to stay at the forefront of bearing technology, but they also prioritize customer satisfaction through quality manufacturing, extensive testing, and robust support services. This commitment to excellence means you get support roller bearings that offer:

Durability: Bearings designed to last, reducing the need for frequent replacements and downtime.

Performance: High-quality materials and precision engineering ensure optimal performance across a wide range of applications.

Reliability: Whether it's standard or custom bearings, THB delivers products you can rely on for your critical machinery.

In the world of industrial machinery, the choice of components can make a substantial difference in performance, efficiency, and reliability. Support roller bearings are pivotal in many applications, and selecting the right ones is crucial. With THB Bearings, you're opting for a brand that not only understands the demands of heavy-duty applications but also provides a product lineup designed to meet these challenges head-on.

By considering factors like load capacity, environmental conditions, maintenance, and the need for customization, and by leveraging the quality and expertise of THB Bearings, you can ensure your machinery operates at its best. Rolling toward reliability starts with choosing the right support roller bearings, and with THB Bearings, that choice becomes a pathway to success.

English

English