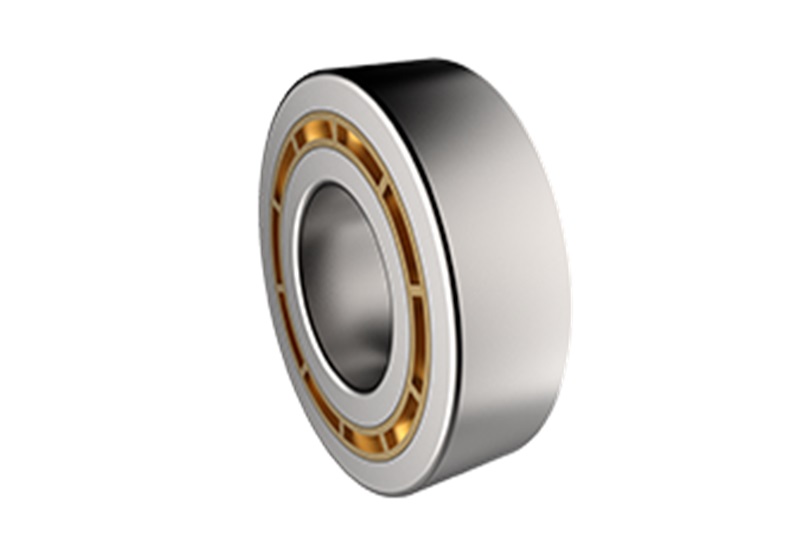

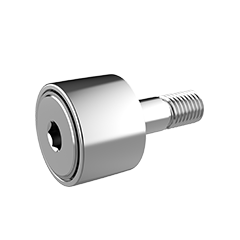

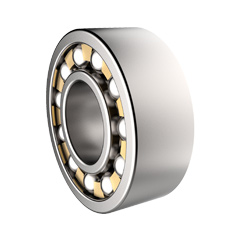

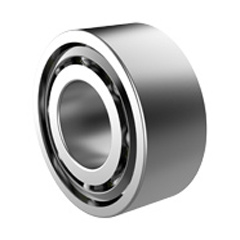

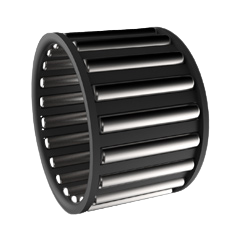

Backing roller bearings are bearing units composed of machined thick-walled outer rings, needle rollers or cylindrical rollers, cage-guided or full-complement rolling element sets, inner rings or bolts, and seals, which can withstand high radial loads and certain The impact load, compact and diverse structure, high rotation accuracy, wide variety, wide adaptability, easy to install. Support roller bearings are widely used in machine tools, metallurgical machinery, textile machinery, printing machinery and other mechanical equipment and processing lines.

1. Understanding of support roller bearings

It is a thick-walled outer ring, quenched by high temperature and high nitrogen, and the high-precision sorting rollers are guided by the ribs of the high-rigidity outer ring. Using linear contact, the rollers can easily rotate directly on the raceway and can withstand huge loads. In order to relieve the stress, the outer ring of the support roller bearing adopts a curved surface design, and the curved roller has a single or double sealing ring.

2. Maintenance of support roller bearings

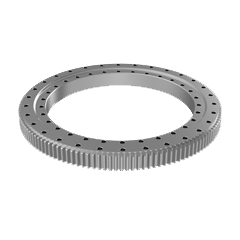

(1) When the support roller bearing leaves the factory, the raceway has been filled with grease, and the surface has been coated with anti-rust oil. According to the needs of customers, the packaging of slewing bearings can be single package or whole package.

(2) If the supporting roller bearing is not installed and used, it should be oiled and maintained every 6 months to prevent corrosion; in the southern region, it should be oiled and maintained every 3 months. Bearing raceways of support rollers need to be lubricated and maintained once a year. During maintenance, the support roller bearings should be rotated to check whether the operation is flexible. After all maintenance, the support roller bearings should be restored to their original state and packed with film.

(3) Like other industrial bearing types, support roller bearings also should be stored in a dry, flat room without corrosive media, and should not be soaked or submerged in water.

(4) The supporting roller bearings should be placed stably, avoiding vertical or inclined placement. When laying flat (except the entire steering assembly), at least 3-5 buffer blocks should be evenly distributed in the circumferential direction between each slewing bearing, and the upper and lower blocks should be consistent in the circumferential position. Support roller bearings that have been in use for many years (especially in places where it rains) should be inspected.

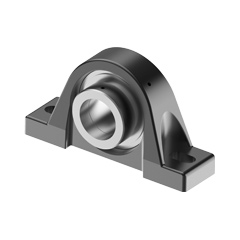

The bearing bush is an important part of the bearing, and it is the contact part between the sliding bearing and the journal. Whether the structural design of the bushing is reasonable or not has a great influence on the performance of the bearing. It is a tile-like semi-cylindrical shape with a very smooth surface. It is usually made of bronze, anti-friction alloys and other wear-resistant materials. In special cases, it can be made of wood, engineering plastics or rubber. Sometimes in order to save precious materials or structural needs, a layer of bearing alloy is usually poured or rolled on the inner surface of the bush, which is called bearing bushing. The bushing should have certain strength and rigidity, and it should be positioned reliably in the bearing, so that it is easy to input lubricant, easy to dissipate heat, and easy to assemble, disassemble and adjust.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano