Professional Equipment: Using High-Precision, Reliable, and Highly Stable CNC Lathes

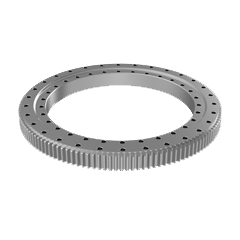

The most critical and final manufacturing process in bearing ring production is grinding. The main equipment used includes specialized CNC grinding machines and ultra-deep machining CNC lathes.

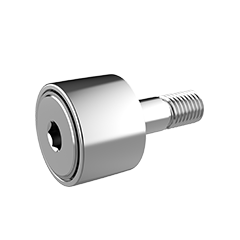

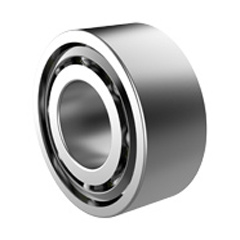

For some types of bearing rings with sime geometric shapes and low precision requirements, some deep groove ball bearing manufacturers (China) opt for cost-effective CNC machines controlled by PLCs. However, for certain categories of deep groove bearing rings with higher precision demands—such as raceways that must be manufactured with a convex profile—our deep groove ball bearing manufacturers (China) should use general-purpose or high-end CNC machines to meet the standards.

High Precision and Consistency for Deep Groove Ball Bearing Manufacturers (China)

Apart from differences in raw materials and heat treatment processes, precision and related issues mainly manifest in parts grinding, especially in maintaining high precision and consistency during large-scale production.

Reputable deep groove ball bearing manufacturers (China) typically achieve a first-pass yield rate of around 80%, with a matching rate (assembly compatibility) of about 60%. Some bearing types (e.g., tapered roller bearings for wind turbine shafts) also struggle to maintain quality above the P4 grade.

Core Technologies and Measures of Deep Groove Ball Bearing Manufacturers (China)

High-Precision CNC Machines

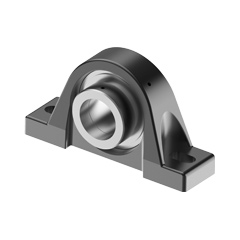

A top manufacturer should use CNC lathes with high precision, reliability, and stability. For bearing rings with more complex shapes, multifunctional CNC grinding machines must be applied. Internal surface grinding should use fast high-speed electric spindles, while external surface grinding should employ spindle bearings with high bending stiffness and noise suppression for rapid grinding.

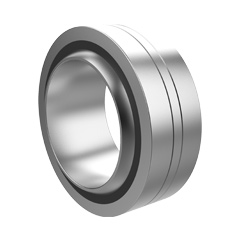

Deep groove ball bearing manufacturers (China) use semi-closed-loop and closed-loop servo control systems for precise control, enabling ultra-fine feeding and compensation. Feed resolution can reach 0.25μm or even 0.1μm, with repeat positioning accuracy at 1μm or as high as 0.5μm.

High-precision, high bending stiffness, and wear-resistant ball screws and linear guides are standard moving components in such equipment.

Additionally, deep groove ball bearing manufacturers (China) should utilize machine beds with excellent aging stability and vibration damping, such as granite beds, which feature strong vibration attenuation and low thermal expansion coefficients for higher precision CNC grinding machines.

Strict Measurement and Grinding Control

Accurate measurements should guide grinding operations, targeting control precision of 3μm or better, even down to 1μm. AC servo motors are used to drive and control wheel dressers to reduce wheel dressing intervals and improve wheel quality. High-quality diamond and CBN grinding wheels are employed to ensure consistent shape precision in mass production.

Advanced Heat Treatment and Processing

Deep groove ball bearing manufacturers (China) should optimize forging, deep processing, or high-precision cold rolling to reduce grinding volume. Additional quenching and cryogenic treatments should be fully implemented between processes to eliminate grinding residual stress and prevent defects like grinding burns or cracks caused by excessive cutting speeds, thereby improving machining accuracy and surface quality.

Focus on Key Components Manufacturing

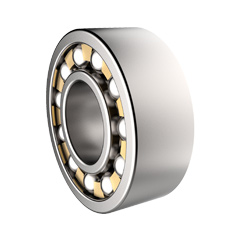

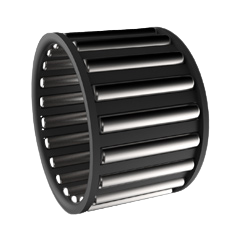

Attention should be paid to improving the manufacturing standards of rollers, balls, and other critical components. Automated production lines are especially necessary for high-precision cylindrical and tapered rollers. Such rollers must be thoroughly stabilized and hardened.

Strict Processing Environment Control

Deep groove ball bearing manufacturers (China) should establish or upgrade production environments with stringent temperature and humidity control, vibration reduction, and cleaning requirements.

Skill Training and Quality Assurance

Deep groove ball bearing manufacturers (China) must highlight the "grasp and inheritance" of high-precision component manufacturing characteristics by enhancing technical training and practical experience accumulation of operators. Strict process discipline and quality management systems should be enforced, aligning "software" (skills and processes) with "hardware" (equipment) to maximize hardware efficiency and performance.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano